CNC car parts are integral to the automotive industry, offering precision and efficiency in production. In this article, we’ll discuss the common car parts made with CNC machining, their manufacturing techniques, and the factors that affect production efficiency. Whether you’re designing engine blocks or transmission components, CNC machining offers a reliable solution for creating high-quality car parts.

Obsah

- Introduction to CNC Car Parts

- Common CNC Car Parts List and Their Machining Techniques

- Factors Affecting the Efficiency of CNC Car Parts Production

- Save Costs and Boost Efficiency in CNC Car Parts

- Advancements in CNC Technology for Car Parts Manufacturing

- Závěr

- Nejčastější dotazy

Introduction to CNC Car Parts

CNC machines are revolutionizing the way car parts are manufactured. These parts are key components that ensure optimal performance and safety in vehicles. CNC machining offers unparalleled precision and versatility, making it the preferred choice for producing custom car parts at scale.

Can a CNC Machine Make Car Parts?

Yes, CNC machines can manufacture a wide range of car parts, from engine components to transmission gears. The precision and accuracy of CNC machines make them ideal for creating parts that must meet exacting specifications.

Why Are CNC Car Parts in High Demand?

CNC car parts are in high demand because they provide high precision, repeatability, and the ability to produce complex geometries. Additionally, the efficiency of CNC machining leads to reduced manufacturing time and costs, making it an attractive option for automotive manufacturers.

Common CNC Car Parts List and Their Machining Techniques

In the automotive industry, CNC machining is used for a wide variety of car parts. These parts can be divided into two main categories: engine components and transmission components. Each requires specific machining techniques to ensure durability, precision, and performance.

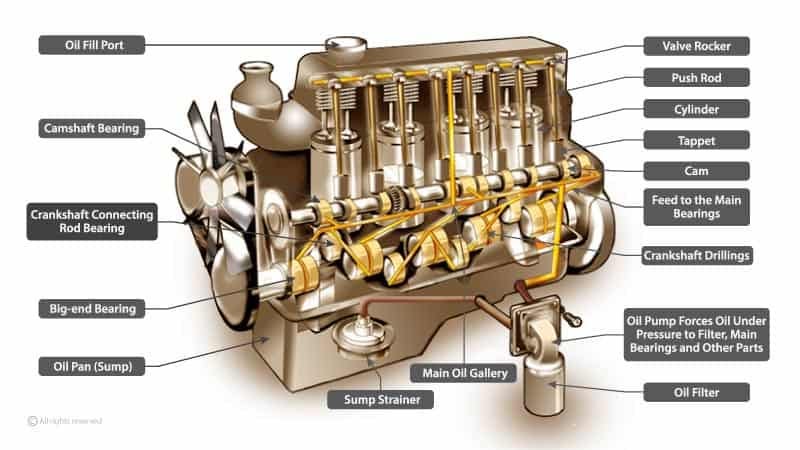

Car Engine Parts Names With Pictures

The engine is the heart of a car, and CNC machining is used extensively to create engine components that meet exacting performance standards. Below are common engine parts manufactured with CNC machining:

| Car Engine Part | Materiál | Machining Technique |

|---|---|---|

| Engine Blocks | Aluminum, Cast Iron | CNC frézování |

| Crankshafts | Ocel | CNC Turning & Grinding |

| Cylinder Heads | Aluminum, Cast Iron | CNC frézování |

CNC Milling for Aluminum Engine Blocks

CNC milling is commonly used for machining aluminum engine blocks due to its ability to remove material efficiently while maintaining tight tolerances.

CNC Turning and Grinding for Steel Crankshafts

CNC turning and grinding are used to create the precise dimensions needed for steel crankshafts, which must be extremely strong and durable to withstand the engine’s rotational forces.

Transmission Components Names With Pictures

Transmission components are essential for transferring power from the engine to the wheels. These parts require precise machining to ensure smooth operation under heavy loads.

| Transmission Part | Materiál | Machining Technique |

|---|---|---|

| Ozubená kola | Steel, Alloy Steel | CNC Gear Hobbing |

| Transmission Shafts | Ocel | CNC broušení |

CNC Gear Hobbing for Precision Gears

CNC gear hobbing is used to cut gears with high precision, ensuring that they mesh correctly and operate smoothly within the transmission system.

CNC Grinding for Transmission Shafts

CNC grinding is used to achieve the necessary smooth surface finish and tight tolerances required for transmission shafts.

Demand Parts For More Advanced Customization

As automotive technology advances, there’s a growing demand for custom parts that cater to specific performance needs, such as lightweight racing parts or components for electric vehicles (EVs).

Profiling and Milling for Lightweight Racing Parts

Profiling and milling are used to create lightweight racing parts, which need to be both strong and light to improve vehicle performance on the track.

Drilling and Milling for EV Cooling Plates

EV cooling plates are critical for regulating battery temperature, and CNC machining ensures that these components are manufactured to precise specifications for efficient cooling.

Factors Affecting the Efficiency of CNC Car Parts Production

Several factors influence the efficiency of CNC car parts production. These include tooling and equipment selection, material choices, and process optimization.

Tooling and Equipment Selection

Matching Cutting Tools to Materials

Choosing the right cutting tools for the material being machined is crucial for achieving the desired finish and maintaining tool life. Different materials, such as aluminum or steel, require different tools.

Choosing Multi-Axis CNC Machines for Complex Parts

Multi-axis CNC machines, such as 5-axis CNC machines, are ideal for machining complex parts with intricate geometries. They offer greater flexibility and precision than traditional 3-axis machines.

What Does Engineers Use To Build The Parts

Different Materials: Aluminum vs Titanium vs Steel

Engineers select materials based on the specific performance requirements of the part. For example, aluminum 6061 is lightweight and easy to machine, while titanium and steel offer superior strength for high-stress components.

Programming and Process Optimization

Traditional Toolpaths vs. Adaptive Toolpaths

Adaptive toolpaths adjust the cutting path in real-time based on the material being cut, improving efficiency and reducing wear on tools compared to traditional toolpaths.

Save Costs and Boost Efficiency in CNC Car Parts

One of the key advantages of CNC machining is its ability to save costs and boost efficiency in car parts production.

Cutting Costs with CNC Automation

CNC automation reduces labor costs and increases production rates, making it an ideal solution for large-scale production of car parts.

Reducing Waste with Precision Machining

Precision machining minimizes material waste, ensuring that car parts are made with the least amount of scrap possible, thereby lowering production costs.

Efficient Solutions for Large-Scale Production

With the ability to produce car parts at high volumes with minimal error, CNC machining offers an efficient solution for large-scale production needs in the automotive industry.

Custom CNC Parts at Affordable Costs

CNC machining allows for affordable production of custom parts, even for small runs, making it an accessible option for custom car parts at competitive prices.

Advancements in CNC Technology for Car Parts Manufacturing

CNC and 3D Printing for Prototyping

Combining CNC machining with 3D printing allows for faster prototyping of car parts, enabling engineers to test designs before full-scale production begins.

Choosing TUOFA Precision CNC Machining Car Parts

TUOFA provides high-quality, precision CNC machining services for custom car parts, ensuring that your parts are made with the highest standards of accuracy and durability.

Závěr

CNC machining offers a precise, efficient, and cost-effective solution for producing custom car parts. Whether for performance vehicles or mass-market cars, CNC machining enables manufacturers to create parts with intricate designs and high precision, meeting the demands of the automotive industry.

Nejčastější dotazy

How to price CNC parts?

The cost of CNC parts is typically determined by factors such as material, complexity, size, and volume. Be sure to provide detailed specifications when requesting a quote.

Why are CNC Parts So Expensive?

CNC parts can be expensive due to the high precision required, the cost of materials, and the time it takes to program and set up the machines.

Can a CNC Machine Make Motorcycle Parts?

Yes, CNC machines can also make motorcycle parts, including engine components, frames, and other custom parts, with the same level of precision used in car parts manufacturing.