Indholdsfortegnelse

- What is CNC Machining?

- Is CNC Machinist a Hard Job?

- How Hard Is It to Learn CNC Machining?

- Is CNC Programming Hard to Learn?

- How Hard Is It to Run a CNC Machine?

- Common Challenges in CNC Machining

- Can CNC Machining Be Done by Anyone?

- CNC Machining and CNC Programming: Two Sides of the Same Coin?

- How Technology Is Changing the Difficulty of CNC Machining

What is CNC Machining?

Definition and Overview of CNC

CNC stands for Computer Numerical Control. It uses computers to control machines that cut or shape materials.

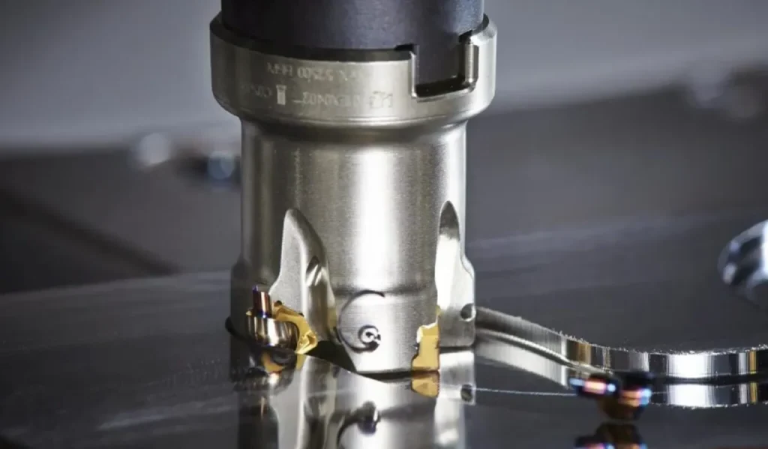

Key CNC Machining Processes

| Proces | Beskrivelse |

|---|---|

| Fræsning | Cutting material with a rotating tool to shape the workpiece. |

| Drejning | Rotating the workpiece while a tool cuts it to shape. |

| Boring | Using a rotating drill to make round holes in materials. |

What Does CNC Stand For?

CNC stands for Computer Numerical Control. It allows machines to perform precise operations with high automation.

Is CNC Machinist a Hard Job?

Understanding the Job Requirements

A CNC machinist operates machines to create precise parts. The job needs knowledge and experience in machine handling and setup.

Skills Needed to Be a CNC Machinist

Technical Knowledge

CNC machinists must know how to read blueprints, operate machines, and understand CAD/CAM software.

Physical Demands of the Job

The job requires standing for long periods, lifting heavy materials, and handling machinery safely.

Is CNC Machinist a Good Career?

CNC machinists have stable jobs. The demand for them is high in many industries.

Job Stability and Growth Potential

The CNC machining field is growing, offering many opportunities for skilled workers.

CNC Machinist Salary Expectations

| Experience Level | Salary Range (per year) |

|---|---|

| Entry-level | $35,000 – $45,000 |

| Mid-level | $50,000 – $60,000 |

| Experienced | $65,000 – $75,000 |

How Hard Is It to Learn CNC Machining?

CNC Machining for Beginners: Challenges and Rewards

Learning CNC machining can be tough at first. But with practice, it becomes easier.

How Long Does It Take to Learn to Be a CNC Machinist?

Training Programs and Timeframe

It takes around 1 to 2 years to finish training. But learning on the job can continue after formal training.

Factors Affecting the Learning Curve

| Faktor | Impact on Learning Time |

|---|---|

| Previous Experience | People with mechanical skills learn faster. |

| Machine Type | Some machines are easier to use than others. |

| Training Quality | Good training speeds up learning. |

Is CNC Machining Hard to Learn? Insights from Industry Experts

Learning CNC Skills from Scratch

Experts say it’s challenging but not impossible. Practice is key to mastering CNC machining.

Transitioning from Manual to CNC Machining

If you know manual machining, learning CNC becomes easier because you already understand some concepts.

Is CNC Programming Hard to Learn?

Understanding CNC Programming Basics

What Is CNC Programming?

CNC programming tells the machine how to move. It uses a special language called G-code to control machine actions.

Role of CNC Programmers

CNC programmers create the code that guides machines to make parts. They need to understand both the machine and the design.

How Hard Is It to Learn CNC Programming?

Difficulty of Programming Languages (G-code, M-code)

Learning G-code can be hard at first. But once you get used to it, it becomes easier.

Essential Programming Skills

Key skills include understanding machine operations, reading blueprints, and writing error-free code.

Learning CNC Programming: Step-by-Step Approach

Start with basic commands. Gradually move to more complex tasks. Use software tools to help create the programs.

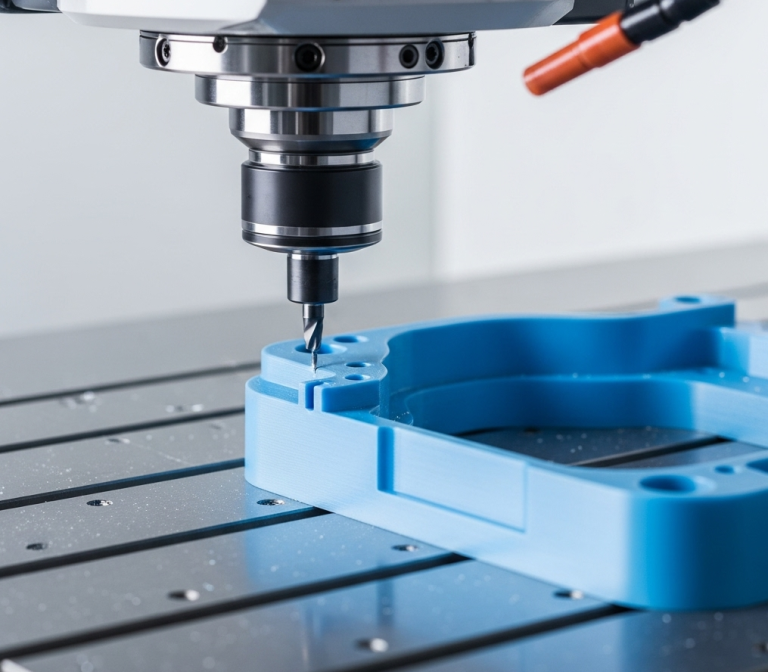

How Hard Is It to Run a CNC Machine?

Operating CNC Machines: What You Need to Know

Running a CNC machine needs focus. You must load materials, set up tools, and check machine settings.

CNC Machine Setup: The First Step

Set up the correct program and make sure the tools and materials are in place before starting the machine.

Maintaining Precision and Avoiding Errors

Handling Tool Changes and Calibration

Change tools carefully. Calibrate machines to ensure accuracy.

Troubleshooting Common Issues

Operators often fix issues like tool wear or program errors. Being able to troubleshoot is important.

Is It Hard to Run a CNC Machine? Real Operator Experiences

Many machinists say it gets easier with experience. The first time can be hard, but practice makes it manageable.

Common Challenges in CNC Machining

Machine Setup and Calibration Difficulties

Getting the machine ready is one of the hardest parts. Calibration is important for accuracy.

Dealing with Material Variability and Handling

Different materials behave differently. You need to adjust your approach based on the material you’re using.

Managing Tool Wear and Machine Maintenance

Preventive Maintenance Practices

Regular maintenance helps prevent problems. Keep machines clean and lubricated.

Replacement and Adjustments

Sometimes, parts of the machine wear out. Be ready to replace them or make adjustments.

Can CNC Machining Be Done by Anyone?

Entry-Level vs. Advanced CNC Machining

Anyone can start learning CNC, but experience makes you better. Advanced machinists handle more complex tasks.

Do You Need Experience to Start CNC Machining?

No. Beginners can learn. Training programs help you get started.

Is CNC Machining Hard for Everyone?

Transitioning from Other Trades to CNC

If you have experience in other fields like manual machining or engineering, you may find CNC machining easier.

Overcoming Initial Learning Challenges

It’s normal to face challenges at first. Stay patient and practice regularly.

CNC Machining and CNC Programming: Two Sides of the Same Coin?

CNC Machining and CNC Programming: Differences and Overlaps

CNC machining is the physical part, while CNC programming involves writing the code that controls the machine.

Is CNC Programming Harder Than CNC Machining?

Complexity of CNC Programming

CNC programming can be harder at first because it requires learning a new language and understanding how machines work.

Key Differences in the Learning Process

Machining requires hands-on work, while programming needs more theory and logic.

How Technology Is Changing the Difficulty of CNC Machining

Automation and Its Impact on CNC Machines

Automation makes CNC machining easier by reducing manual tasks.

CNC Machine Automation vs. Manual Operations

Automated machines require less effort and can produce higher quality work with less human intervention.

AI and Machine Learning: Future of CNC Programming

AI is making CNC programming smarter and easier. It helps with error detection and optimizing processes.

Will Technology Make CNC Machining Easier?

Yes, in the future, automation and AI will make CNC machining faster and less complicated.