Sisällysluettelo

Johdanto

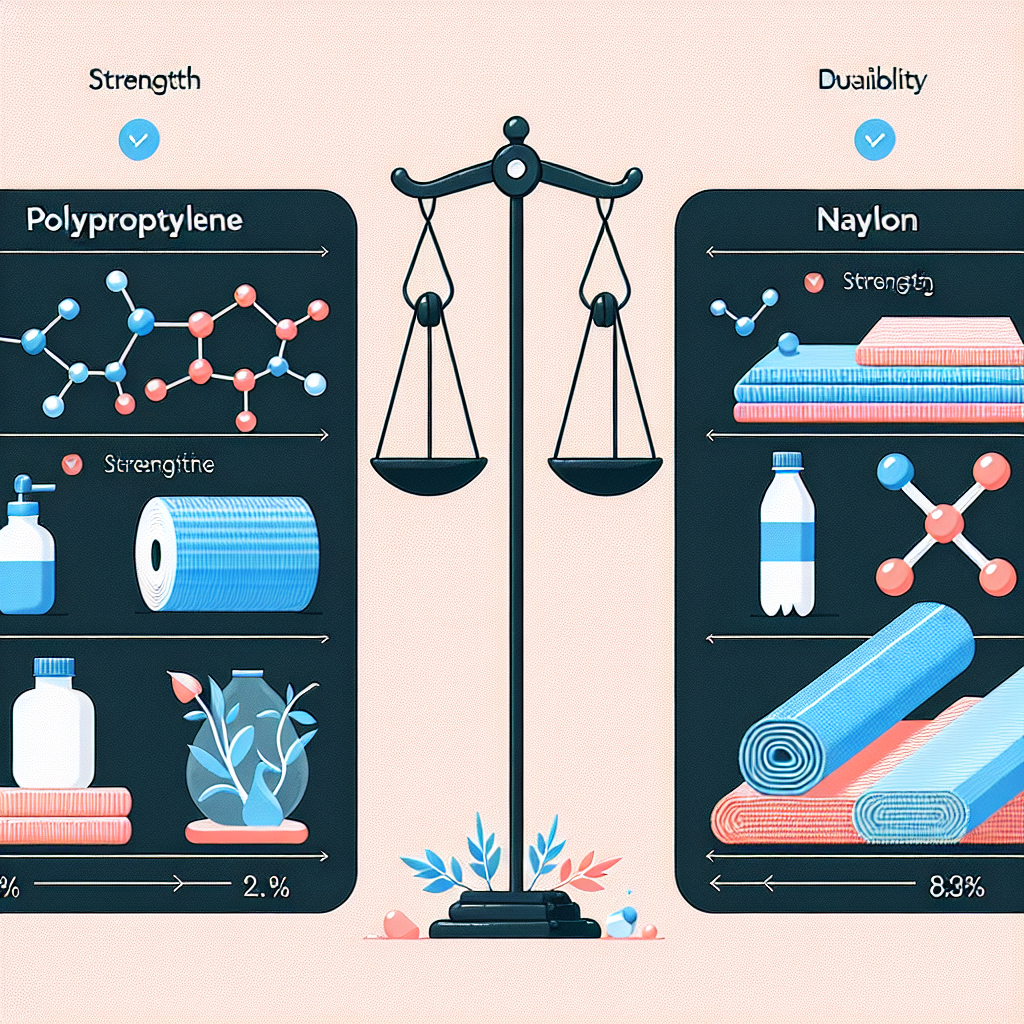

- Polypropylene and nylon are synthetic polymers widely used in various applications.

- Polypropylene is lightweight, chemically resistant, and has low moisture absorption.

- Nylon is known for its strength, durability, and abrasion resistance.

- Comparing tensile strength and impact resistance shows nylon generally has superior capabilities.

- The choice depends on specific application requirements, including environmental conditions and mechanical demands.

Comparing Tensile Strength: Polypropylene vs. Nylon

- Polypropylene:

- Thermoplastic polymer with excellent chemical resistance and insulating properties.

- Commonly used in packaging, textiles, automotive components, and consumer goods.

- Tensile strength varies from 30 to 35 MPa.

- Nylon:

- Synthetic polymer known as polyamides, engineered for high strength.

- Used in automotive parts, mechanical components, and high-quality textiles.

- Tensile strength ranges from 45 to 80 MPa.

- Higher tensile strength due to hydrogen bonds between polymer chains.

- Moisture Impact:

- Nylon absorbs water, potentially reducing tensile strength.

- Polypropylene is hydrophobic, maintaining its properties better under wet conditions.

- Conclusion:

- Nylon is generally stronger in tensile strength.

- Choose based on application requirements such as cost, chemical resistance, and environmental conditions.

Durability Differences: Polypropylene and Nylon in Outdoor Applications

- Polypropylene:

- Excellent chemical resistance and moisture resistance.

- Resistant to water absorption, maintaining structural integrity over time.

- Poor resistance to UV radiation unless treated with stabilizers.

- Nylon:

- High tensile strength and elasticity, ideal for mechanical stress applications.

- Higher moisture absorption rate, affecting mechanical properties.

- Susceptible to UV degradation unless treated.

- Enhancements:

- UV stabilizers improve resistance to sunlight for both materials.

- Blending and surface treatments can enhance mechanical properties.

- Conclusion:

- Polypropylene is better for chemical and moisture resistance.

- Nylon is stronger and more elastic, suitable for mechanical stress applications.

- Choose based on environmental conditions and application requirements.

Cost-Effectiveness: Analyzing Polypropylene and Nylon for Budget-Conscious Projects

- Polypropylene:

- Versatile, chemically resistant, and fatigue-resistant.

- Lighter and generally less expensive than nylon.

- Lower production costs and simpler polymerization process.

- Nylon:

- Superior resistance to abrasion and high temperatures.

- Higher production costs and more energy-intensive processes.

- Innovations:

- High-performance polypropylene grades narrow the performance gap with nylon.

- Conclusion:

- Polypropylene is more cost-effective for budget-conscious projects.

- Choose based on specific performance requirements and budget constraints.

Chemical Resistance: Polypropylene vs. Nylon in Industrial Uses

- Polypropylene:

- Excellent chemical resistance, suitable for containers and pipelines.

- Stable performance in chemically aggressive environments.

- Nylon:

- Resistant to many solvents but more susceptible to strong acids and oxidizing agents.

- Higher moisture absorption rate affects chemical resistance.

- Conclusion:

- Polypropylene generally offers superior chemical resistance.

- Choose based on specific chemical exposure and performance requirements.

Temperature Tolerance: How Polypropylene Stands Up Against Nylon

- Polypropylene:

- Melting point: 160 to 170 degrees Celsius.

- Suitable for lower temperature applications.

- Maintains properties down to -20 degrees Celsius.

- Nylon:

- Higher melting point: around 250 degrees Celsius.

- Better performance in high-temperature environments.

- Remains ductile in cold temperatures.

- Conclusion:

- Nylon is more temperature-tolerant and versatile.

- Choose based on temperature requirements of the application.

Environmental Impact: Assessing the Sustainability of Polypropylene and Nylon

- Polypropylene:

- Lower production energy and fewer emissions.

- Non-biodegradable but easier to recycle than nylon.

- Nylon:

- Energy-intensive production with higher emissions.

- Durable, leading to longer-lasting products.

- More challenging to recycle due to various formulations.

- Conclusion:

- Polypropylene generally has a lower environmental impact.

- Choose based on sustainability priorities and recycling capabilities.

Application Specifics: When to Choose Polypropylene Over Nylon

- Polypropylene:

- Excellent chemical resistance and stability in humid conditions.

- Ideal for chemical containers, outdoor furniture, and automotive parts.

- Nylon:

- Superior tensile strength and flexibility.

- Best for high-stress mechanical applications and high-temperature environments.

- Conclusion:

- Polypropylene is preferred for chemical resistance and stability.

- Nylon is better for strength and high-temperature applications.

Longevity and Wear: Examining the Lifespan of Polypropylene Compared to Nylon

- Polypropylene:

- Robust and resistant to various chemical solvents, bases, and acids.

- Less dense and more resistant to moisture absorption.

- Nylon:

- Notable tensile strength and flexibility.

- Hygroscopic nature can lead to reduced mechanical strength in moist environments.

- Conclusion:

- Polypropylene offers better longevity in corrosive and moisture-prone environments.

- Nylon provides superior performance in mechanical stress applications.

Päätelmä

- Nylon generally exhibits higher tensile strength and better resistance to abrasion.

- Polypropylene is lighter, more chemically resistant, and cost-effective.

- Choose the material based on specific application requirements and environmental conditions.

Newsletter Updates

Enter your email address below and subscribe to our newsletter