디자인에 기반한 맞춤형 CNC 부품

매 순간 정밀성 - 고객의 비전, 당사의 CNC 전문성. 비즈니스 요구에 맞는 신뢰할 수 있는 중국 CNC 가공 견적을 제공합니다.

모든 프로덕션 파일은 안전하고 기밀이 유지됩니다.

ISO 9001:2015 IATF 16949

프로젝트를 위한 확장 가능한 제조 서비스

가공 견적 확장 가능한 제조 서비스는 프로젝트의 규모와 복잡성에 맞게 조정하여 대규모 생산 또는 프로젝트의 세부적인 맞춤형 작업을 위한 정밀도와 품질을 보장합니다.

800개 이상의 기업을 위한 CNC 가공 견적

작동 방식

문의를 시작하는 방법

디자인 및 프로토타이핑

생산 프로세스

포장 및 배송

품질 검사 프로세스

가공 견적 제조업체로서 모든 제품이 최고 수준의 정밀도와 품질을 충족하도록 보장하기 위한 품질 검사 팀의 포괄적인 품질 보증 프로세스를 강조하고 싶습니다. 품질 검사를 수행하는 방법은 다음과 같습니다:

지원팀은 제품 배송 또는 서비스 완료 직후 고객 만족도 설문조사를 실시하여 최근 경험에 기반한 피드백을 제공합니다. 고객 피드백에 응답하고 제품 및 서비스를 개선합니다. 제품 보증 3개월, 보증 기간 동안 제조 오류 등 결함이 있는 부품의 무상 수리 또는 교체를 약속합니다.

프로젝트 제작의 예

중국의 CNC 가공 공장으로서 당사는 다양한 프로젝트를 수행한 것을 자랑스럽게 생각합니다.

해양 엔지니어링: 고유한 설계 및 엔지니어링 도전과제스마트 홈

산업 장비의 정밀도와 복잡성 달성

엔지니어와 디자이너가 관심을 가질 만한 기사

Bead Blasting: Clean, Uniform, And Matte Finishes

Bead blasting drives fine media at high speed to strip scale, blend machining marks, or create a satin…

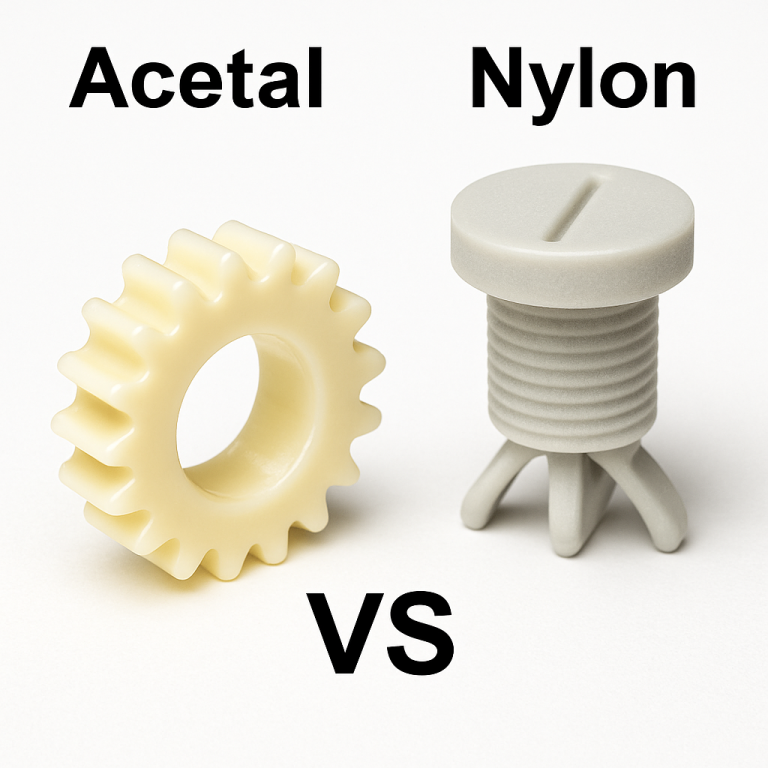

Acetal Vs Nylon: Choose The Right Engineering Plastic

Acetal (POM) and nylon (PA) are two go-to engineering plastics for gears, bushings, and structural housings. They look…

Fiberglass Melting Point: A Complete Guide

Fiberglass weaves silica glass strands into cloth, mat, or rovings. Unlike metals that melt at one point, fiberglass…