Request a CNC Machining Quote for Superior Mechanical Parts

Why settle for average when you can have superior? By requesting a quote from us, you’re taking the first step towards unparalleled precision and quality in your mechanical parts.

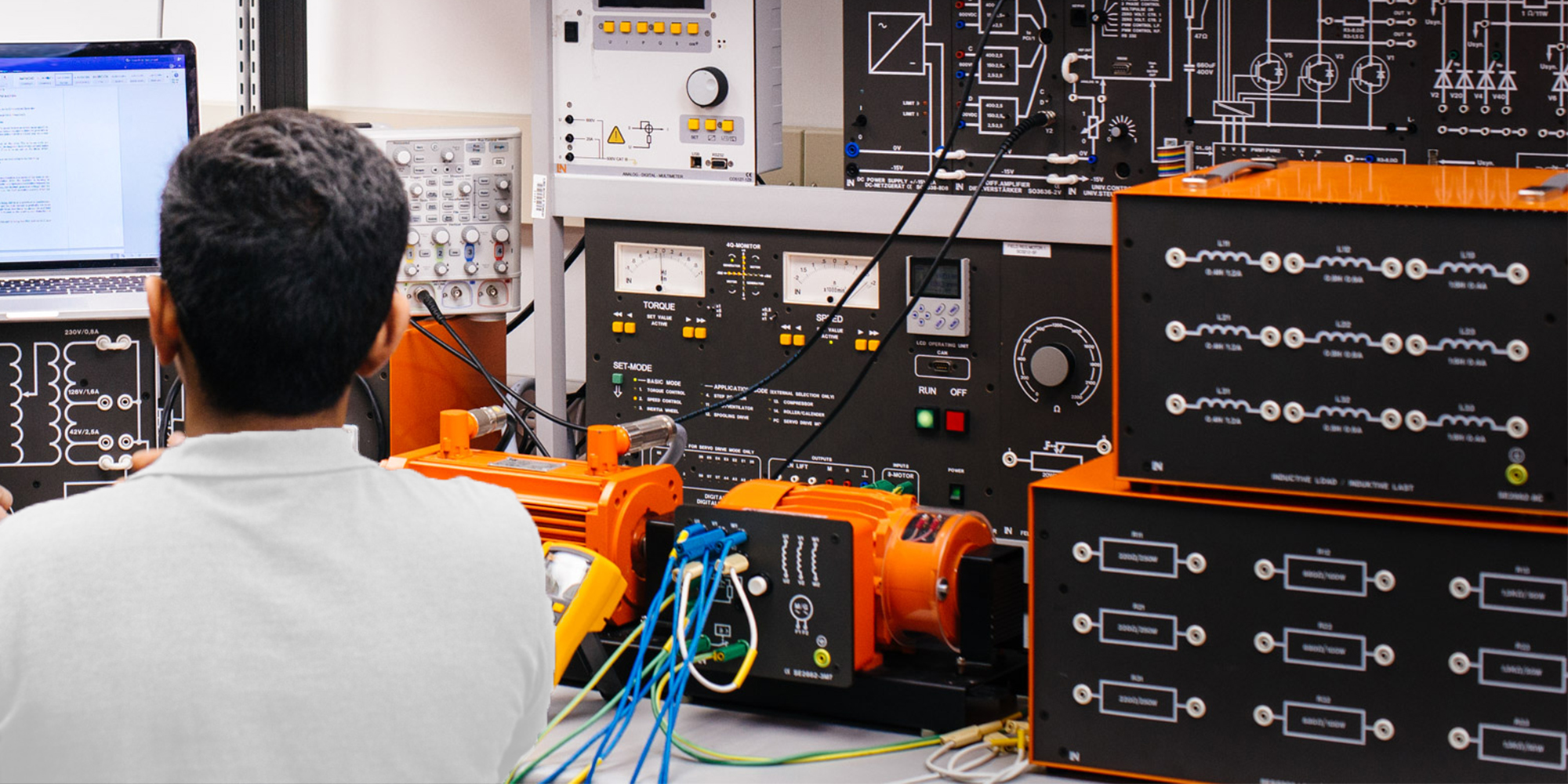

Enhance Your Electrical Engineering with Superior Material

Aluminum 6061, 7075

Ideal for lightweight structural components such as frames and casings due to their excellent strength and machinability.

Stainless Steel 304, 316

Perfect for creating durable and corrosion-resistant parts like gears, valves, and fasteners in various equipment.

Titanium Ti-6Al-4V, Ti-5Al-2.5Sn

Used in high-performance components such as turbine blades and hydraulic systems, offering strength and corrosion resistance under extreme conditions.

Carbon Steel A36, 1018

Commonly used for manufacturing robust machinery parts like brackets, bases, and structural supports.

Copper Alloys C360, C101

Essential for precision electrical connectors, heat sinks, and cooling systems due to their superior conductivity.

Precision CNC Mechanical Parts: Durability Meets Quality

Discover durable, quality components crafted from advanced materials, designed for automotive, medical, electronics, industrial machinery, and energy sectors. Achieve peak performance and reliability with our expertly manufactured parts.

Why Mechanical Parts Companies Choose Machining Quote

Mechanical Components and Accessories Manufacturing Capabilities

- Machining Quote excels in processing a broad spectrum of materials, including aerospace-grade alloys and engineering plastics. Our CNC centers are adept at intricate geometries and tight concentricity, crucial for advanced mechanical components.

- Our 5-axis machining technology enables the production of complex designs with superior surface finishes, ideal for precision components requiring detailed shapes and undercuts in a single setup.

- We provide comprehensive sheet metal services, from laser cutting and precision bending to welding, complemented by surface treatments like powder coating and anodizing to enhance both durability and aesthetics.

Equipment Parts Post-Processing Service

At Machining Quote, 50 surface finishing services ensure each component meets the rigorous demands of the mechanical equipment industry with enhanced functionality and longevity.