Sheet Metal Fabrication Services for Custom Metal Parts

Get a Free Quote From China Factory Now! Discover how cost-effective your project can be with our precision sheet metal fabrication.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication offers a host of advantages that make it a preferred method for producing metal parts and assemblies across various industries. Here’s why it’s widely used:

- Versatility

- High Efficiency

- Durability

- Cost-Effectiveness

- Lightweight Products

- Scalability

- Aesthetic Options

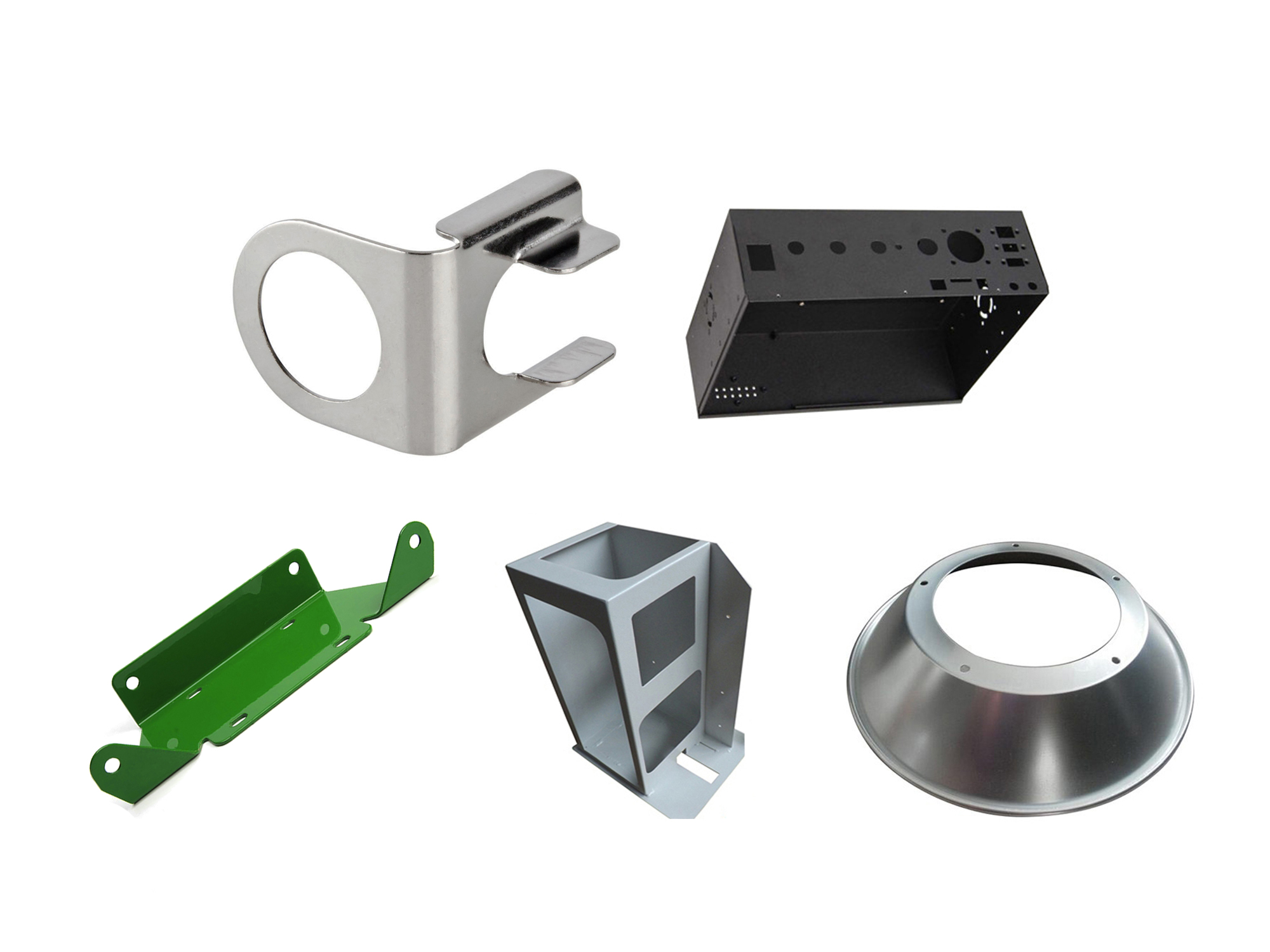

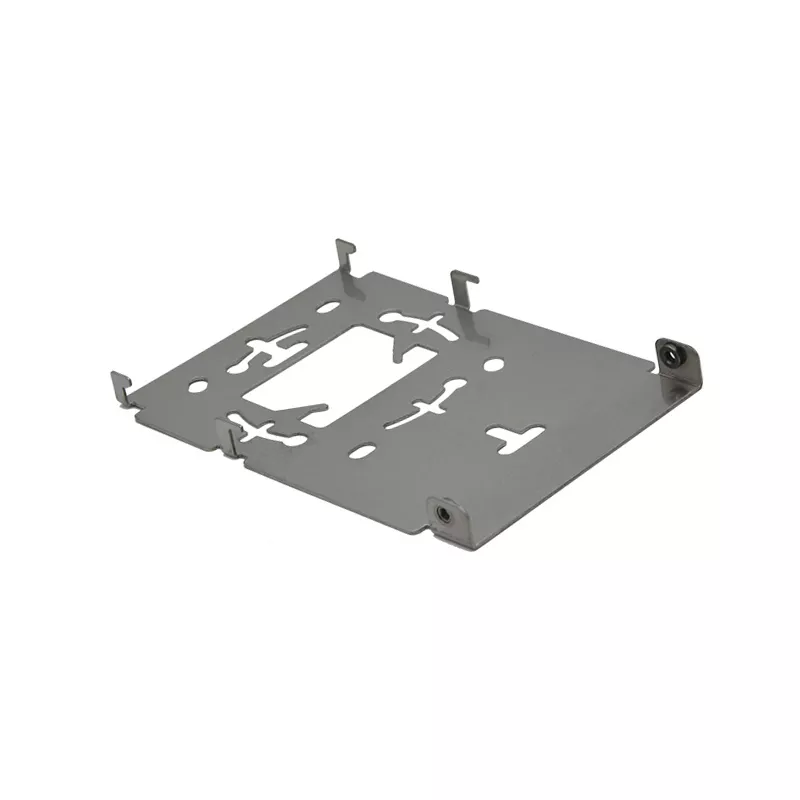

Sheet Metal Parts and Applications

These parts demonstrate the flexibility and utility of sheet metal in providing essential components for a multitude of applications, from industrial machinery to consumer products and infrastructure.

- Enclosures – Protects and houses electronic or mechanical equipment.

- Brackets – Supports structures in buildings and machinery.

- Panels – Forms exterior sections of vehicles and industrial machines.

- Chassis – Serves as the base frame for computers, electronics, and automotive components.

- Housings – Encases devices to protect internal components from environmental factors.

- Ducts – Channels for directing airflow in HVAC systems.

- Cabinets – Storage units in industrial, office, or residential settings.

- Roofing – Forms the protective outer layer of buildings.

- Beams – Structural components in buildings and large machinery.

- Shelves – Metal structures for holding items in storage or display settings.

- Signs – Metal substrates for advertising or informational displays.

Metal Fabrication Process with Machining Quote

Sheet Metal Fabrication Specifications and Tolerances

This table provides a clearer picture of precision and comprehensive service capabilities, highlighting a strong commitment to quality and global reach in sheet metal fabrication services.

| Feature | Description |

|---|---|

| Blank Size | 12′ x 25′ (3.66 m x 7.62 m); accommodates larger volumes upon request. |

| Standard Lead Time | 1-3 business days |

| Sheet Thickness | 0.020” – 0.300” typical; accommodates thicker or thinner gauges upon request. |

| General Tolerances | +/- 0.005” for flat parts; +/- 0.020” for multi-planed bent parts; +/- 0.5 degree for bend angles. |

| Braking (Hydraulic) | 12’ length, fingers from 3” – 6” |

| Braking (Magnetic) | 7 tons of magnetic pull across the entire beam, 1/2″ minimum reverse bend |

| Punching | 2″ diameter hole capacity, or larger upon request |

| Certifications | ISO 9001 (Quality Management), ISO 14001 (Environmental Management), AS9100 (Aerospace Standard) |

| Design and Engineering Support | Available assistance in design optimization and engineering |

| Prototyping | Capabilities for producing prototypes available |

| Production Volume | Good for: From 1 prototype to millions of parts |

| Geographical Coverage | Global shipping and delivery services available |

Sheet Metal Material Options

Aluminum

Aluminum is a lightweight, corrosion-resistant metal ideal for applications requiring a high strength-to-weight ratio and good thermal conductivity. It’s easy to machine and extensively used in aerospace, automotive, and consumer electronics. Common types of aluminum alloys like 6061 and 7075 offer enhanced mechanical properties, such as improved toughness and hardness.

- Price: $$

- Lead Time: 10 days

- Wall Thickness: 0.75 mm

- Tolerances:+/-0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Copper

Copper is highly conductive to both heat and electricity, making it popular in electrical applications, heat exchangers, and automotive parts. It is relatively easy to machine and provides a unique combination of ductility, strength, and thermal conductivity. Its natural resistance to corrosion and aesthetic appeal also make it a choice material for decorative applications.

- Price: $$$

- Lead Time: =10 days

- Wall Thickness: 0.75 mm

- Tolerances: plusmn;0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Brass

Brass is an alloy of copper and zinc, known for its machinability and corrosion resistance. It’s often used for decorative items, plumbing fixtures, electrical components, and musical instruments. Brass provides a balance between strength and ductility and can be easily machined into complex shapes.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel is renowned for its corrosion resistance and strength. It’s widely used in food processing equipment, medical devices, and general metal fabrication. Stainless steel alloys, like 304 and 316, offer a good balance of corrosion resistance, machinability, and cost-effectiveness. It’s a versatile material suitable for a wide range of applications.

- ?Price: $$

- ?Lead Time: < 10 days

- ?Wall Thickness: 0.75 mm

- ?Tolerances: ±0.125mm (±0.005″)

- ?Max part size:200 x 80 x 100 cm

Titanium

Titanium is known for its exceptional strength, lightweight, and high corrosion resistance. It’s often used in aerospace, medical implants, and high-performance automotive applications. Titanium is challenging to machine but offers superior mechanical properties and a very high strength-to-weight ratio, making it ideal for advanced engineering applications.

- ?Price: $$$$$

- ?Lead Time: < 10 days

- ?Wall Thickness: 0.75 mm

- ?Tolerances: ±0.125mm (±0.005″)

- ?Max part size: 200 x 80 x 100 cm

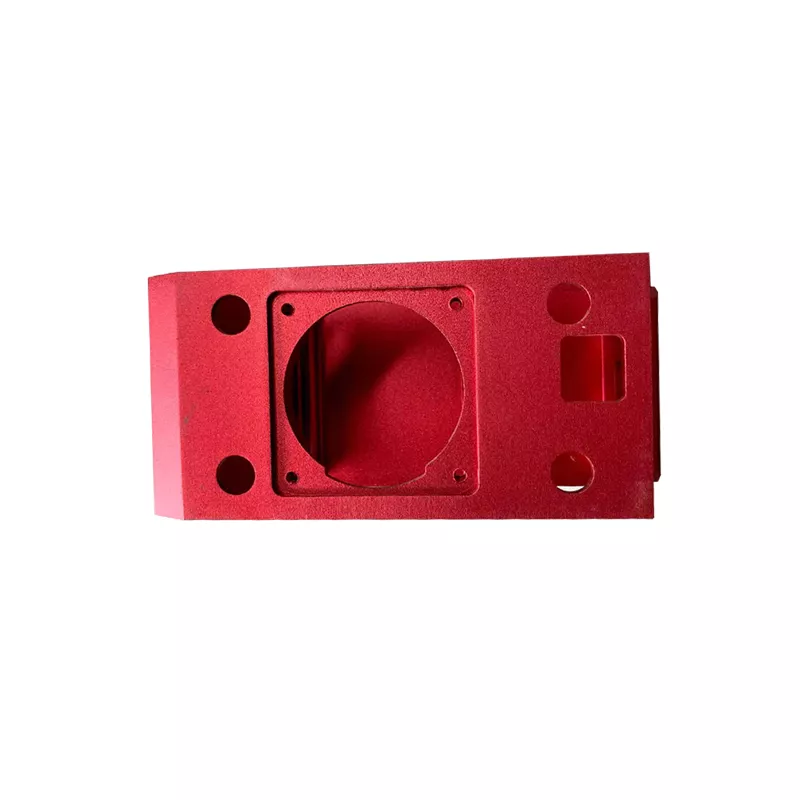

Post Processing Services for Sheet Metal Parts

Post-processing services enhance the functionality and appearance of sheet metal parts, meeting specific industry standards and increasing the value of the final product.

Painting

Powder Coating

Plating

Anodizing

Sandblasting

Brushing

Polishing

Heat Treatment

Assembly

Screen Printing