Table of Contents

- Introduction

- Comparing Mechanical Properties: PP vs POM

- Chemical Resistance of PP and POM Plastics

- Temperature Tolerance: PP vs POM in Extreme Environments

- Machinability Factors: Working with PP and POM

- Cost-Effectiveness: Analyzing PP and POM for Budget-Conscious Projects

- Applications and Industries: Where PP and POM Shine

- Longevity and Durability: PP vs POM Lifespan Comparison

- Environmental Impact: Assessing the Sustainability of PP and POM

- Conclusion

Introduction

In plastic machining, choosing the right polymer is crucial for performance and durability. Polypropylene (PP) and Polyoxymethylene (POM) are popular options, each with unique benefits. PP is known for its chemical resistance and welding properties, making it ideal for harsh environments. POM offers high stiffness, low friction, and excellent dimensional stability, perfect for precision parts in high-performance applications. Understanding these materials helps engineers and designers select the right one for their projects.

Comparing Mechanical Properties: PP vs POM

PP Mechanical Properties

PP is a semi-crystalline thermoplastic with great chemical resistance and toughness. It can bend repeatedly without breaking, making it ideal for applications like living hinges. PP also has good electrical resistance, used in containers and parts exposed to chemicals. However, its tensile strength is lower than POM, limiting its use in load-bearing applications.

POM Mechanical Properties

POM, or Acetal, has high strength, stiffness, and hardness, suitable for precision parts with high dimensional stability. Its low friction and excellent wear resistance make it great for gears and bearings. POM can handle significant mechanical stress, preferred for continuous or high-load parts.

Application and Cost Considerations

POM’s superior properties come at a higher cost. PP is more cost-effective and adequate for many applications, while POM is chosen for specialized, high-performance needs. The decision depends on the specific mechanical demands and cost constraints of the application.

Chemical Resistance of PP and POM Plastics

PP Chemical Resistance

PP resists most acids, alkalis, and solvents at room temperature, making it ideal for chemical tanks and laboratory equipment. Its non-polar structure ensures resistance to many chemicals. However, PP is less resistant to organic solvents and oxidizing agents.

POM Chemical Resistance

POM is resistant to hydrocarbons, solvents, and neutral chemicals but susceptible to strong acids and alkalis. It performs well in automotive applications involving petrol, diesel, and lubricants. POM maintains integrity under thermal cycling but degrades faster in harsh chemical environments compared to PP.

Application and Cost Considerations

PP offers better chemical resistance for environments with aggressive chemicals. POM is suitable for applications needing high mechanical stress and chemical exposure like fuel systems. The choice depends on the specific chemical environment and mechanical demands.

Temperature Tolerance: PP vs POM in Extreme Environments

PP Temperature Tolerance

PP operates between -20 to 130 degrees Celsius, ideal for flexible parts in chemical environments without extreme temperatures. Higher temperatures can deform PP and reduce its mechanical properties.

POM Temperature Tolerance

POM handles -40 to 140 degrees Celsius, suitable for higher and lower temperature applications than PP. POM’s thermal stability and resistance to creep make it ideal for precision parts under thermal stress.

Application and Cost Considerations

In automotive applications with fluctuating temperatures, POM is preferred for parts requiring precision and minimal thermal expansion. PP is chosen for interiors and non-load-bearing parts. The choice depends on temperature exposure and performance requirements.

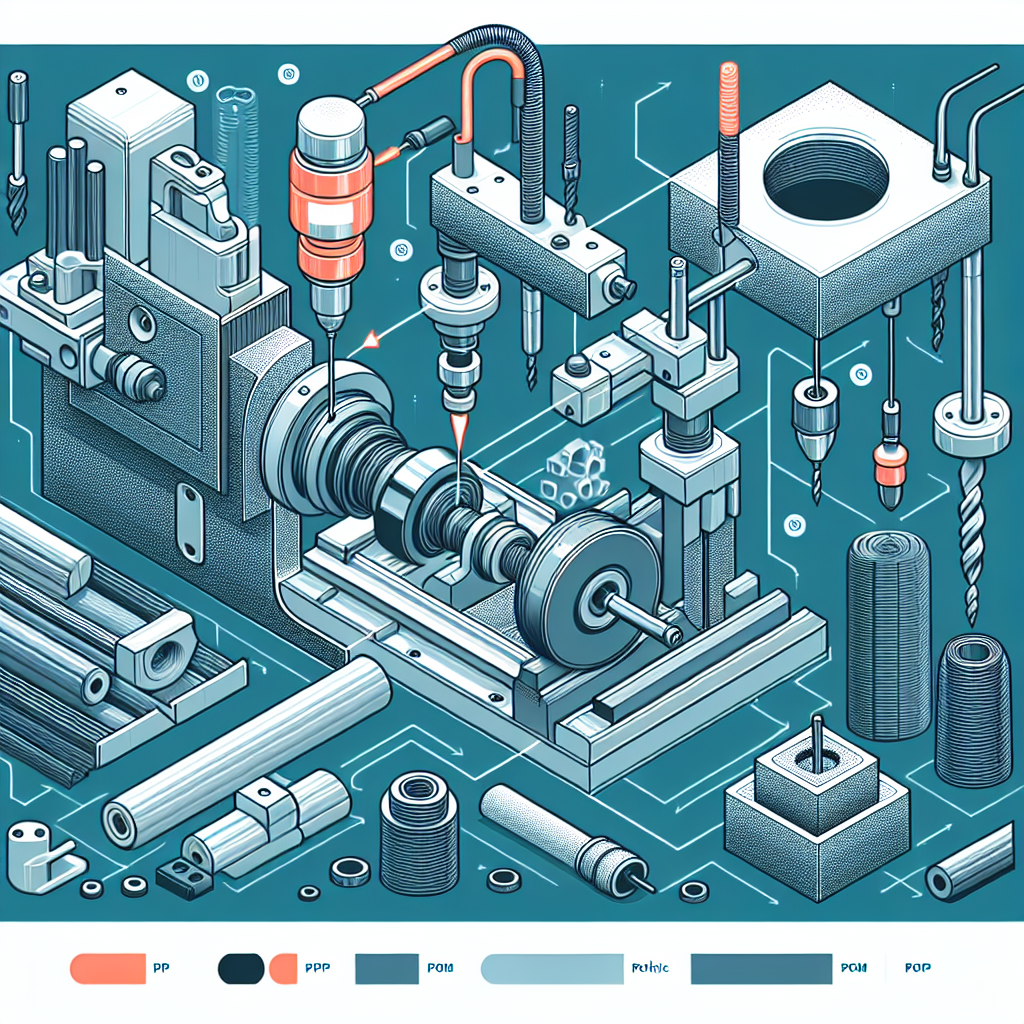

Machinability Factors: Working with PP and POM

PP Machinability

PP’s softness and low melting point can cause material build-up on tools and poor finishes. Its elasticity can absorb cutting energy, causing deflection and inaccuracies. Using sharp, polished tools and cooling techniques helps mitigate these issues.

POM Machinability

POM’s stiffness and low friction make machining easier, with smooth finishes and accurate dimensions. POM’s higher density and hardness facilitate better machinability but require careful monitoring to prevent thermal degradation.

Application and Cost Considerations

The choice between PP and POM depends on the part’s use and environment. PP is suitable for flexible, chemical-resistant parts, while POM is ideal for precision parts under high stress. Advanced machining techniques like CNC machining ensure precise control over cutting parameters, optimizing material use and quality.

Cost-Effectiveness: Analyzing PP and POM for Budget-Conscious Projects

PP Cost-Effectiveness

PP is less dense and easier to machine, reducing tool wear and maintenance costs. Its lower cost per volume makes it ideal for large-scale production.

POM Cost-Effectiveness

POM offers superior mechanical properties but at a higher cost. Its higher price per kilogram reflects its enhanced attributes and production complexity. POM is more abrasive on equipment, increasing tool wear and maintenance costs.

Application and Cost Considerations

PP is cost-effective for applications with moderate performance requirements. POM is ideal for high-performance parts despite higher costs. Consider total lifecycle costs, including maintenance and replacement, to determine the most cost-effective material.

Applications and Industries: Where PP and POM Shine

PP Applications

PP is used in chemical processing, automotive parts like bumpers and dashboards, and consumer goods like containers and toys. Its low density and chemical resistance make it suitable for various applications.

POM Applications

POM is used in precision parts like gears, bearings, and medical devices. Its high stiffness, low friction, and dimensional stability make it ideal for high-stress and high-precision applications.

Application and Cost Considerations

The choice between PP and POM depends on the specific requirements of the application, including mechanical stress, environmental conditions, and regulatory standards. Selecting the appropriate material ensures optimal performance and cost-effectiveness.

Longevity and Durability: PP vs POM Lifespan Comparison

PP Longevity

PP’s chemical resistance ensures durability in harsh environments. It has good fatigue resistance but is limited by a lower melting point and UV susceptibility.

POM Longevity

POM’s high strength and wear resistance contribute to its durability. It operates at higher temperatures and has better dimensional stability. However, it is more susceptible to chemical attack from strong acids and bases.

Application and Cost Considerations

PP is suitable for chemical handling and consumer goods, while POM is ideal for high-performance engineering applications. Consider environmental conditions and mechanical demands to select the most durable material.

Environmental Impact: Assessing the Sustainability of PP and POM

PP Sustainability

PP is recyclable and does not contain harmful chemicals like BPA. Improving recycling rates can enhance its sustainability. Its lower melting point reduces energy consumption during production.

POM Sustainability

POM’s production involves formaldehyde, posing environmental risks. It is less biodegradable and persistent in the environment, contributing to microplastic pollution. Its higher energy consumption and emissions profile make it less sustainable than PP.

Application and Cost Considerations

PP is generally more sustainable, especially with improved recycling. POM’s use should be carefully considered for applications where alternatives may offer similar benefits with less environmental impact. Advanced recycling technologies and biodegradable alternatives are crucial for reducing the environmental footprint of these polymers.

Conclusion

Choosing between PP and POM for plastic machining parts depends on the application’s specific mechanical and environmental demands. PP is cost-effective and suitable for chemically harsh environments, while POM offers superior mechanical properties for high-precision and high-stress parts. Consider total lifecycle costs, environmental impact, and regulatory requirements to make the best material choice for your project.