Enhance Your Designs with Custom Acrylic CNC Machining Services

Specializing in delivering precision-cut parts that maintain acrylic’s superior optical clarity and durability, we ensure your specifications are met with the highest quality.

Pluses and Minuses of Acrylic Plastic

Acrylic plastic, often known by its commercial names like Plexiglas or Lucite, is a popular material used in various applications due to its specific properties. Here are some of the pluses and minuses of using acrylic plastic:

| Pluses | Minuses |

|---|---|

| Optical Clarity | Scratch Sensitivity |

| Transmits up to 92% of visible light, clearer than glass. | More prone to scratches than glass and some plastics. |

| Impact Resistance | Cost |

| More impact resistant than glass, suitable for safety applications. | High-quality acrylic can be more expensive than other plastics. |

| Weather Resistance | Heat Sensitivity |

| Highly resistant to weather changes, ideal for outdoor use. | Can deform under high temperatures, limiting some uses. |

| Lightweight | Chemical Sensitivity |

| Lighter than glass, easier to handle and install. | Susceptible to damage from certain chemicals and solvents. |

| Machinability | Fragility to Stress |

| Easy to machine, cut, drill, and finish; versatile for manufacturing. | Can crack or shatter under stress, especially if not properly supported. |

| Aesthetic Flexibility | Environmental Impact |

| Easily colored, molded, and shaped for decorative purposes. | Acrylic is not biodegradable and can contribute to plastic pollution. |

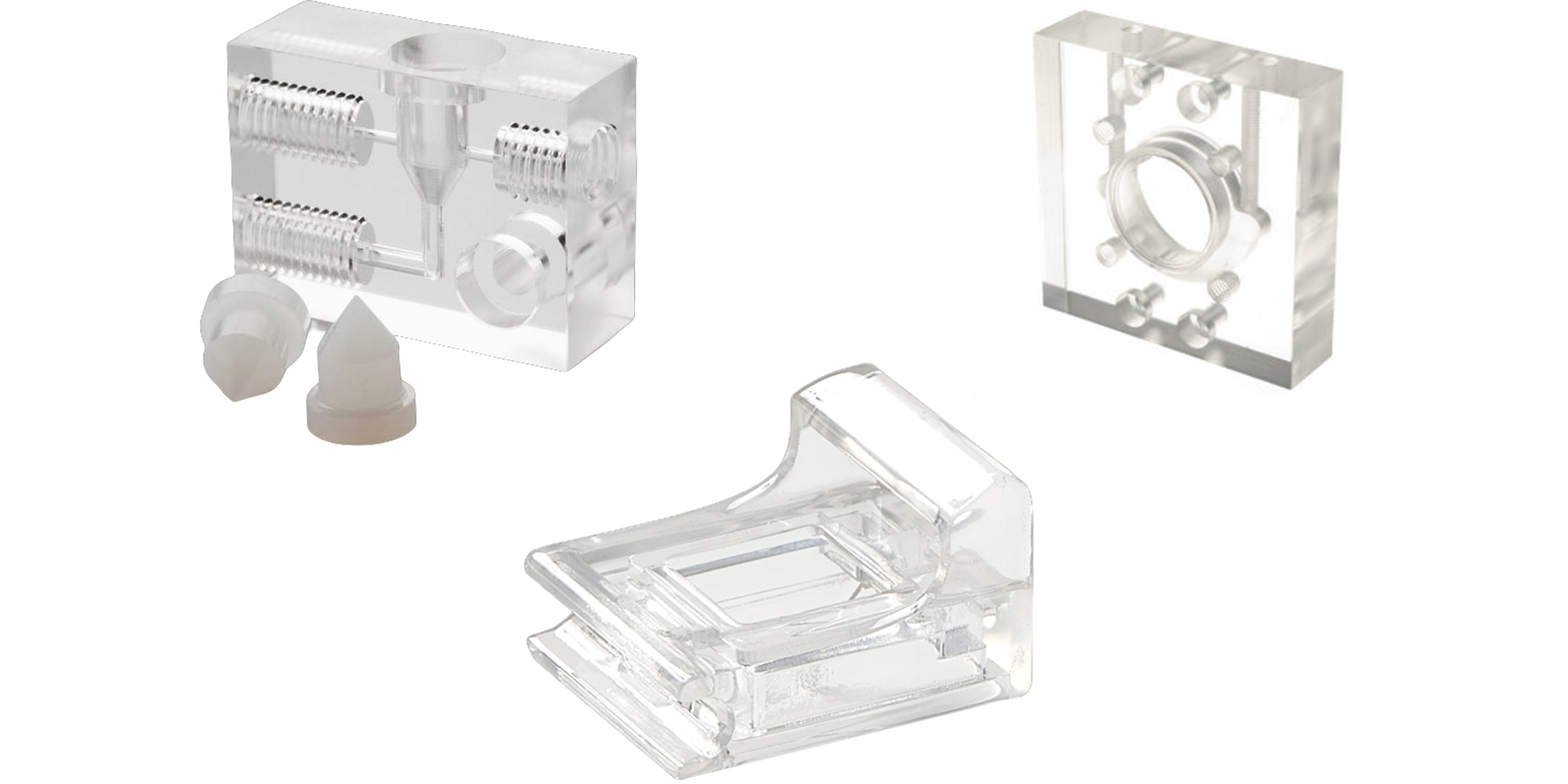

Acrylic CNC Machining Parts and Used

Custom CNC machining of acrylic parts enables the production of complex, precise designs consistently, making it crucial for industries needing clear, durable custom solutions.

Physical Properties of Acrylic Material

These properties showcase acrylic’s strength, clarity, and durability, essential for engineers and designers to evaluate its suitability for applications like optical components, structural elements, and consumer goods.

| Property | Value | Units | Description |

|---|---|---|---|

| Density | 1.18 g/cm³ | g/cm³ | Measures the mass per unit volume, indicating material heaviness. |

| Tensile Strength | 65 MPa | MPa | The maximum stress acrylic can withstand before breaking. |

| Modulus of Elasticity | 2.6 – 3.2 GPa | GPa | Indicates the stiffness of acrylic, affecting its deformation under stress. |

| Impact Strength | 0.15 – 0.35 kJ/m² | kJ/m² | Acrylic’s ability to absorb impact without fracturing. |

| Light Transmittance | Up to 92% | Percentage | High transparency, making it suitable for optical applications. |

| Heat Deflection Temperature | 95 °C | °C | The temperature at which acrylic deforms under a specified load. |

| Coefficient of Thermal Expansion | 70 x 10^-6 /°C | 1/°C | Describes how much acrylic will expand or contract with temperature changes. |

CNC Machining Tips for Acrylic Plastic

CNC machining acrylic plastic needs special skills and methods to get good results. Here are five tips for CNC machining acrylic, based on Machining Quote expert advice and reliable sources.

| CNC Machining Aspect | Specific Parts | Parameters & Techniques | Purpose & Benefit |

|---|---|---|---|

| Tool Selection for Acrylic | General acrylic parts | Single or double-flute carbide end mills, diamond-cut routers | Provides sharp cuts, maintains clarity and finish, reduces stress on material |

| Optimal Cutting Speeds and Feed Rates | Thin and thick acrylic sheets | 18,000 RPM with 200 IPM for thin sheets; 12,000 RPM for thick sheets | Adjusts speed and feed to minimize chipping and achieve clean cuts |

| Cooling Techniques to Prevent Melting | Lens mounts, light guides | Use mist cooling system or compressed air; keep tool temperature below 160°F | Prevents acrylic from melting during machining, essential for intricate parts |

| Clamping Methods for Stability | Display stands, protective covers | Use vacuum hold-downs instead of direct clamping | Minimizes vibrations and prevents cracking, maintaining dimensional accuracy |

| Efficient Chip Removal | Gear wheels, bushings | High-pressure air blasts at the point of contact | Ensures chips are cleared efficiently, preventing them from sticking back to the part |

CNC Turning and CNC Milling for Acrylic Parts

CNC turning and CNC milling are two precision machining processes widely used for shaping acrylic parts. Each method brings specific advantages to the machining of acrylic, depending on the part’s design and function.

Post Processing Service

Post-processing services are vital for enhancing the aesthetics, functionality, and precision of CNC machined acrylic parts. Here’s a list of common services:

Yes, acrylic is relatively easy to machine. It’s softer than many metals, forms large chips that are easy to remove, and can achieve a smooth finish. However, it’s important to manage heat buildup to prevent melting or warping.