Table of Contents

- Introduction

- Comparing Mechanical Properties: PP vs PEEK

- Thermal Performance in PP and PEEK Machining

- Chemical Resistance of PP vs PEEK Plastics

- Cost-Effectiveness Analysis: PP vs PEEK

- Applications of PP and PEEK in Aerospace and Automotive Industries

- Machining Techniques for PP and PEEK Plastics

- Environmental Impact and Sustainability: PP vs PEEK

- Innovations in PP and PEEK Plastic Machining Technology

- Conclusion

Introduction

PP (Polypropylene) and PEEK (Polyether Ether Ketone) are high-performance plastics used in various industries due to their unique properties. PP is known for its chemical resistance, elasticity, and fatigue resistance, making it suitable for consumer goods and automotive parts. PEEK is known for its high temperature resistance, mechanical strength, and biocompatibility, ideal for aerospace, medical implants, and semiconductor applications. Machining services for these plastics involve precision engineering to create complex parts that meet specific requirements. The choice between PP and PEEK depends on the application’s needs regarding temperature, chemical exposure, strength, and compliance with standards.

Comparing Mechanical Properties: PP vs PEEK

PP Mechanical Properties

PP is a semi-crystalline thermoplastic with excellent chemical resistance, elasticity, and fatigue resistance. It has a low density, making it suitable for applications where weight is critical. Its tensile strength ranges from 25 to 40 MPa, suitable for consumer goods and automotive parts that need significant deformation before breaking. PP is also an excellent insulator, often used in electrical components. However, its operational temperature is limited to around 130°C.

PEEK Mechanical Properties

PEEK is known for its exceptional thermal stability, mechanical strength, and chemical resistance. It can perform at temperatures up to 250°C and intermittently up to 310°C, making it ideal for high-temperature applications in aerospace, automotive, and chemical processing industries. PEEK’s tensile strength ranges from 90 to 100 MPa. It has a high modulus of elasticity, providing stiffness and dimensional stability under mechanical stress and high temperatures. PEEK’s wear and friction characteristics are excellent, making it suitable for dynamic motion applications such as gears and bearings.

Cost and Application

PEEK’s superior mechanical properties come with a higher cost. PP is cost-effective and offers adequate performance for many applications, while PEEK is chosen for specialized applications requiring high-performance characteristics. For long-term exposure to high temperatures and aggressive chemicals, PEEK’s ability to maintain its properties justifies its higher cost.

Thermal Performance in PP and PEEK Machining

PP Thermal Properties

PP has a melting point around 160°C to 170°C, necessitating careful handling during machining to prevent degradation. It has a higher thermal expansion coefficient, leading to potential dimensional changes when exposed to temperature variations. This poses challenges in precision applications.

PEEK Thermal Properties

PEEK has a high melting point of around 343°C, maintaining its properties at elevated temperatures where many plastics fail. It offers excellent thermal stability, ideal for high-performance applications in aerospace, automotive, and medical industries. PEEK’s lower thermal expansion coefficient ensures greater dimensional stability under thermal stress, beneficial for creating precise components. It also has superior heat dissipation, reducing overheating risk and enabling faster machining speeds without compromising integrity.

Chemical Resistance of PP vs PEEK Plastics

PP Chemical Resistance

PP is resistant to bases, acids, and aqueous solutions of salts, making it ideal for containers and pipework in chemical processing industries. However, it is less resistant to organic solvents, oxidizing agents, and chlorinated hydrocarbons.

PEEK Chemical Resistance

PEEK exhibits broader chemical resistance, maintaining performance in both organic and inorganic environments. It withstands harsh chemicals, hydrocarbons, and concentrated acids across a wide temperature range. PEEK does not hydrolyze or lose properties when exposed to water or steam, suitable for high-temperature applications and sterilization processes in medical sectors.

Application and Cost Considerations

While both PP and PEEK offer high chemical resistance, PEEK’s ability to maintain integrity under extreme conditions sets it apart. The choice between PP and PEEK depends on specific application requirements, environmental conditions, and cost considerations. PP offers a cost-effective solution for moderate environments, while PEEK is ideal for demanding applications requiring high strength, stiffness, and chemical resistance.

Cost-Effectiveness Analysis: PP vs PEEK

PP Cost Analysis

PP is cost-effective, offering excellent chemical resistance, elasticity, and fatigue resistance. Its low cost and ease of processing make it popular for automotive parts, consumer goods, and medical devices. PP does not require specialized machinery, reducing initial investment and maintenance costs.

PEEK Cost Analysis

PEEK is a high-performance thermoplastic, ideal for demanding environments such as aerospace, automotive, and medical implants. It has higher raw material prices and requires specialized equipment and skilled operators. Despite higher initial costs, PEEK’s durability and longevity can reduce replacement costs and maintenance frequency in high-stakes industries.

Total Cost of Ownership

While PP is cheaper upfront, its performance limitations could lead to higher overall costs due to failures and replacements. The initial investment in PEEK can be justified by its extended lifespan and reduced need for repairs, particularly in critical applications. Manufacturers must weigh direct costs against operational efficiency and product lifespan to select the most appropriate material.

Applications of PP and PEEK in Aerospace and Automotive Industries

PP Applications

PP is used in automotive bumpers, chemical tanks, gas cans, and car interiors. Its chemical resistance, elasticity, and fatigue resistance make it suitable for these applications. PP’s low cost and ease of fabrication are economically attractive for large-scale production.

PEEK Applications

PEEK is ideal for aerospace components due to its high strength-to-weight ratio, thermal stability, and resistance to chemicals and flame. It is used in engine components, bushings, seals, and back-up rings, requiring precision machining. PEEK’s low smoke and toxic gas emission in fires enhance safety in aerospace applications.

Weight Reduction and Sustainability

Both PP and PEEK contribute to weight reduction in aerospace and automotive industries, enhancing fuel efficiency and reducing emissions. Advanced machining techniques like CNC machining allow for the creation of complex parts with tight tolerances and high-quality finishes.

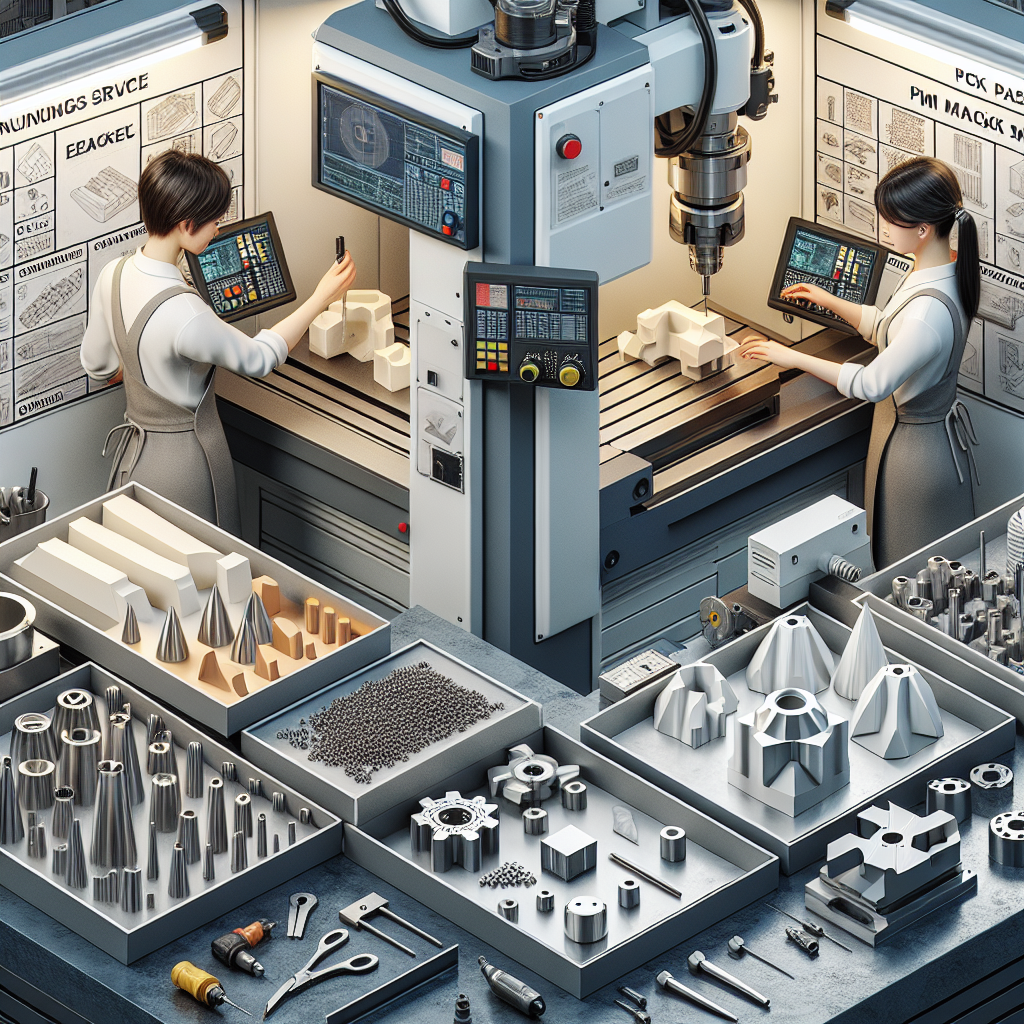

Machining Techniques for PP and PEEK Plastics

PP Machining Techniques

PP requires sharp tools and high-speed machining to minimize resistance and heat generation. Using appropriate cooling measures can reduce thermal and mechanical stresses, preventing warping and poor surface finishes.

PEEK Machining Techniques

PEEK requires wear-resistant tools like polycrystalline diamond (PCD) or tungsten carbide due to its hardness and high melting point. Selecting the right cutting parameters and implementing controlled cooling systems like mist or cryogenic cooling are critical to prevent material degradation and maintain dimensional stability.

Advanced Machining Technologies

Both PP and PEEK benefit from CNC technology, allowing high precision and repeatability in machining complex parts. CNC machines can adjust machining parameters to prevent material melting or deformation. The use of non-toxic, biodegradable cooling fluids improves surface finish and dimensional accuracy, aligning with environmental regulations and sustainability goals.

Environmental Impact and Sustainability: PP vs PEEK

PP Sustainability

PP has a lower environmental impact, being easy to recycle and requiring less energy for production. Its ability to be remolded without significant degradation extends its life cycle, reducing the need for virgin material production and minimizing waste.

PEEK Sustainability

PEEK’s production is energy-intensive, leading to higher CO2 emissions. Its complex molecular structure makes recycling challenging. However, PEEK’s durability means less frequent replacements, which can be considered an environmental benefit in applications where longevity is crucial.

Life Cycle and Innovations

PP’s life cycle is less energy-intensive, with a lower overall environmental burden. Innovations in polymer technology and recycling methods can further reduce energy consumption and waste. PEEK’s chemical recycling processes present an opportunity to enhance its sustainability.

Innovations in PP and PEEK Plastic Machining Technology

Cutting Tool Materials and Geometries

Advancements in diamond-coated tools and PCD tooling offer enhanced durability and precision, reducing tool wear and improving cost-effectiveness in machining PP and PEEK.

Ultrasonic Machining (USM)

USM uses high-frequency sound waves for precise cuts with minimal material wastage, beneficial for creating complex geometries in PEEK without causing thermal damage or stress.

CNC Technology

Advanced CNC machines can manage the unique cutting dynamics of PP and PEEK, ensuring each part is machined to exact specifications with consistent quality. The programmability of CNC machines allows rapid adjustments and fine-tuning of machining parameters.

Cooling and Lubrication Techniques

Non-toxic, biodegradable cooling fluids improve surface finish and dimensional accuracy, aligning with environmental regulations and sustainability goals.

Conclusion

PP and PEEK each offer distinct advantages in plastic machining services. PP is cost-effective, with excellent fatigue resistance and chemical resistance, suitable for less demanding applications. PEEK, while more expensive, offers superior mechanical properties and thermal stability, ideal for high-performance applications. The choice between PP and PEEK depends on specific application needs, balancing performance requirements, environmental conditions, and budget constraints. By understanding the properties and machining techniques of each material, you can make informed decisions to optimize your plastic machining projects.