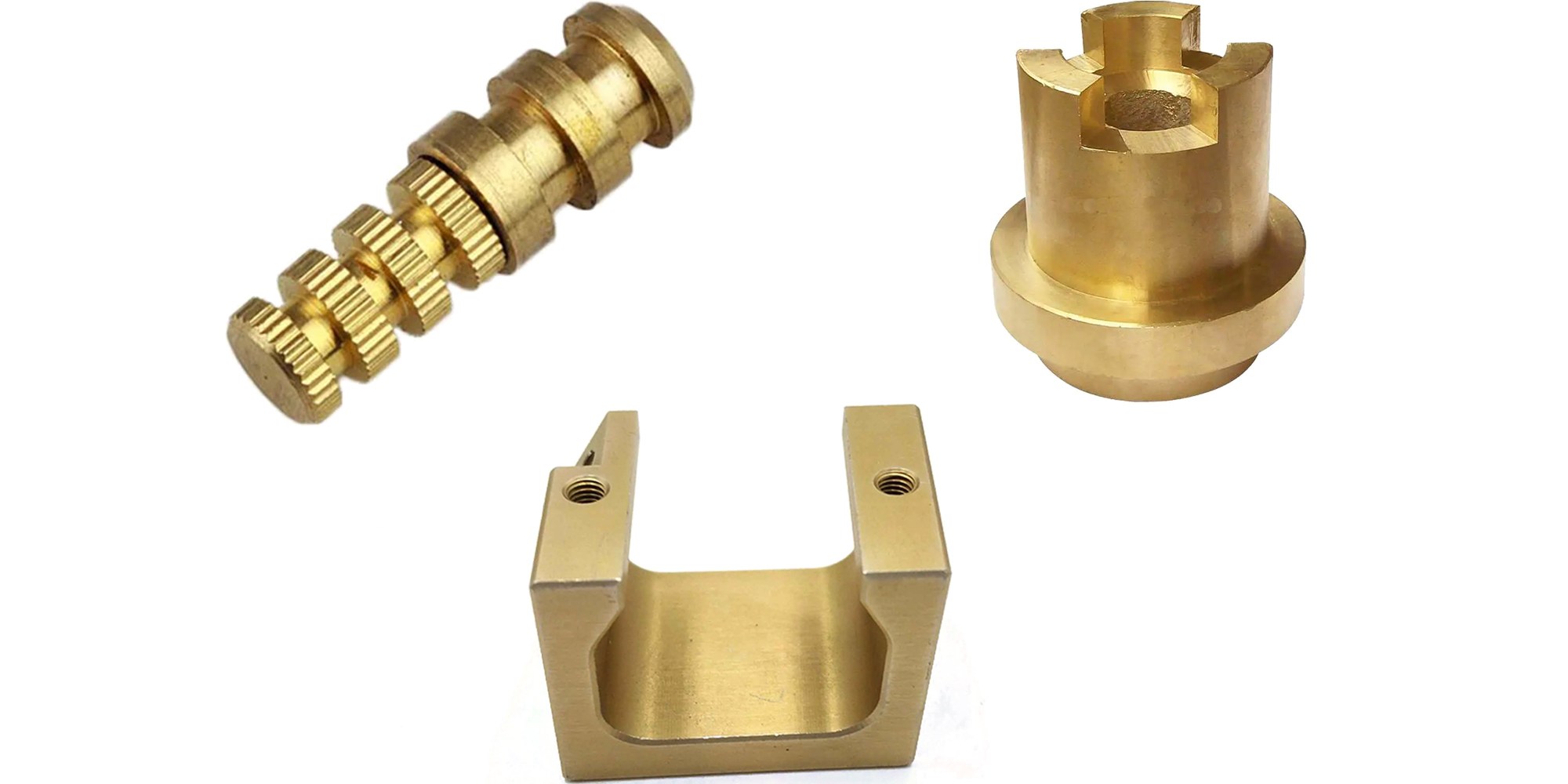

Brass CNC Machining Services by Leading China Factory

Every cut we make marries meticulous precision with artistic finesse, crafting not just parts but legacies in brass. Our state-of-the-art technology and seasoned craftsmanship ensure flawless execution for each project, big or small.

4 Advantages of CNC Brass Parts

High Machinability and Efficiency: Brass is known for its exceptional machinability. It’s softer than steel and iron, which means it requires less energy and time to be machined. This efficiency reduces manufacturing time and costs.

Excellent Corrosion Resistance: Brass is highly resistant to corrosion, which extends the lifespan of the parts. This makes it ideal for applications exposed to water, heat, and corrosive substances.

Aesthetic and Customizable Finishes: Brass has a natural, aesthetically pleasing golden appearance, which is often desirable for visible components in architectural and consumer products.

Conductivity and Non-Magnetic Properties: Brass conducts heat and electricity efficiently, making it suitable for electrical components, connectors, and heat exchangers.

Applications of Custom Brass Machining

Custom brass machining parts, known for their conductivity, corrosion resistance, and ease of machining, are used across industries like electrical, automotive, medical, and more to create essential, diverse components.

- Carburetor Components

- Radiator Components

- Gearbox Components

- Hydraulic Fittings

- Surgical Instrument

- Valves for Oxygen Tanks

- Orthopedic Implants

- Precision Dials and Gears

- Connectors and Contacts

- Sensor Components

- Decorative and Architectural Hardware

- Door Knobs and Handles

- Window Fittings

- Lighting Fixtures

- Hydraulic Fittings and Valves

- Electrical connectors and Sockets

- Valve components and bushing parts

- Lever Style Lock Assembly

Brass CNC Machining Properties

This ranking reflects the general preferences in the industry, with C36000 (Free-Cutting Brass) being the most popular due to its exceptional machinability and good strength, making it a go-to choice for precision parts.

| Brass Grade | Density (g/cm³) | Tensile Strength (MPa) | Hardness (Brinell) | Melting Point (°C) | Elongation (%) | Key Mechanical Properties |

|---|---|---|---|---|---|---|

| C36000 | 8.47 | 430 – 520 | 80 – 150 | 870 – 900 | 53 | Excellent machinability, good strength |

| C26000 | 8.53 | 345 – 485 | 55 – 120 | 950 – 975 | 45 – 60 | High ductility, strength, and corrosion resistance |

| C37700 | 8.44 | 345 – 550 | 90 – 190 | 870 – 910 | 20 – 35 | Good machinability, excellent forgeability |

| C38500 | 8.53 | 345 – 485 | 60 – 100 | 875 – 900 | 53 | Good corrosion resistance, aesthetic appeal |

| C46400 | 8.41 | 310 – 540 | 60 – 150 | 900 – 940 | 20 – 40 | Excellent corrosion resistance, especially in marine environments |

| C28000 | 8.44 | 350 – 500 | 60 – 120 | 910 – 940 | 30 – 40 | Good strength, used in architectural and marine applications |

Brass CNC Machining Capability by Machining Quote

CNC Milling Brass

Used for machining complex brass parts, such as custom mechanical components, decorative items, and engravings.

Brass CNC Turning

Suitable for making axially symmetrical brass parts, like bolts, shafts, and certain connectors.

Brass CNC Grinding

Provides high precision and surface quality, suitable for brass parts requiring high-precision surface finishes.

Brass CNC Threading

For machining precise external or internal threads on brass parts.

Brass EDM Service

Applicable for machining brass parts with complex shapes or small dimensions.

Considerations for Selecting Brass CNC Machining Options

Machine Precision

The level of precision offered by the CNC machine is crucial, especially when working with brass, which is a softer metal that requires careful handling to avoid deformation or inaccuracies. Look for machines with high repeatability and low tolerance levels.

Experienced Mechanics

Our experienced mechanical engineers employ appropriate cutting parameters and tools to improve machining efficiency and part quality, so that the brass parts produced meet high-quality standards, reducing the need for rework and scrap, which can be costly in terms of both materials and time.

Support and Service

Strong after-sales support ensures that any technical issues are resolved quickly, minimizing production delays. Machining Quote is a CNC supplier that provides comprehensive training, technical assistance, and easy access to spare parts.

8 Surface Finishes for CNC Aluminum Parts

Each of these finishes has specific advantages depending on the intended use of your brass parts. Whether you’re looking for improved aesthetics, increased durability, or enhanced resistance to environmental factors, there’s a surface finish that can meet your needs.