Aluminum 7075 is one of the strongest aluminum alloys, making it an excellent choice for CNC turning projects. Its strength, lightweight nature, and corrosion resistance make it highly sought after in industries like aerospace, automotive, and manufacturing. This guide explores why Aluminum 7075 is ideal for CNC turning, the challenges it presents, and tips to achieve precision and quality.

Obsah

- Why Use Aluminum 7075 for CNC Turning?

- Challenges in CNC Turning 7075

- Tools for CNC Turning 7075

- Tips for Precision and Quality

- Post-Turning Treatments

- Applications of 7075 Cylindrical Parts

- FAQs About CNC Turning Aluminum 7075

Why Use Aluminum 7075 for CNC Turning?

Aluminum 7075 is a high-performance alloy that excels in CNC turning. Its unique properties make it suitable for creating strong, lightweight cylindrical components.

What Makes 7075 Good for Cylinders?

Strong and Durable

Aluminum 7075 has a tensile strength of around 572 MPa, making it comparable to some steels. This strength allows it to withstand heavy loads without deforming, ideal for high-performance applications.

Lehké

With a density of 2.81 g/cm³, Aluminum 7075 is much lighter than steel, making it perfect for weight-sensitive designs like aerospace and automotive components.

Key Properties of Aluminum 7075

| Majetek | Hodnota | Significance |

|---|---|---|

| Pevnost v tahu | 572 MPa | High strength for load-bearing applications |

| Hustota | 2.81 g/cm³ | Lightweight for fuel efficiency and mobility |

| Odolnost proti korozi | Mírná | Can be improved with anodizing or coatings |

| Obrobitelnost | Dobrý | Suitable for precision CNC turning |

Why Choose 7075 Over Other Alloys?

Compared to alloys like 6061, Aluminum 7075 offers higher strength and better performance under stress. While it’s more expensive, its superior properties justify the cost in critical applications.

Where Is 7075 Commonly Used?

Aluminum 7075 is used in aerospace parts, automotive components, and high-performance tools. Its strength-to-weight ratio makes it a top choice for demanding environments.

Challenges in CNC Turning 7075

Despite its advantages, CNC turning Aluminum 7075 presents some challenges. Understanding these can help avoid issues during machining.

How Does Hardness Affect Turning?

The high hardness of 7075 can lead to increased tool wear. Using coated tools and slower cutting speeds can mitigate this problem.

What Problems Can Happen with Surface Finish?

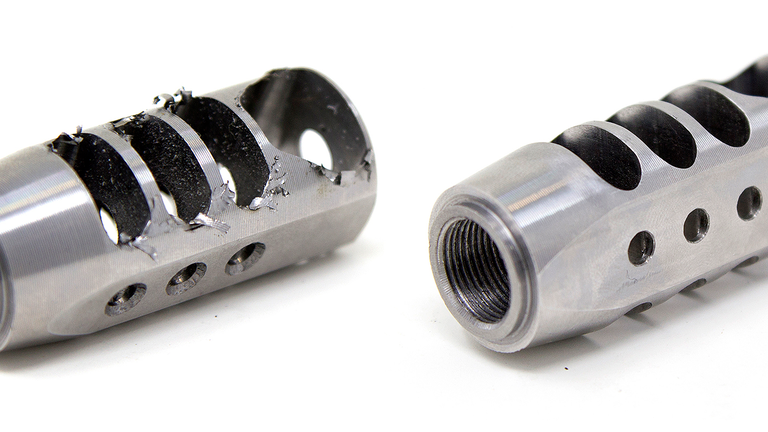

Achieving a smooth surface can be difficult due to Aluminum 7075’s hardness. Proper chip control and coolant application can help improve finish quality.

How to Prevent Tool Wear?

Tool wear is a common challenge when machining Aluminum 7075. Using carbide or diamond-coated tools, along with effective lubrication, can prolong tool life.

Společné výzvy a řešení

| Challenge | Cause | Solution |

|---|---|---|

| Opotřebení nářadí | High hardness | Use carbide or diamond-coated tools |

| Poor Surface Finish | Insufficient chip control | Apply proper coolant and adjust feed rates |

| Generování tepla | Fast cutting speeds | Lower speeds and use lubrication |

Tools for CNC Turning 7075

Choosing the right tools is essential for successfully machining Aluminum 7075. The material’s properties require durable and precise cutting tools.

What Are the Best Cutting Tools?

Coated or Uncoated Tools

Coated tools are recommended for 7075 as they resist wear better and can handle the material’s hardness. Common coatings include titanium nitride (TiN) and diamond-like carbon (DLC).

Why Use Coolant for 7075?

Coolant reduces heat buildup, improves surface finish, and prolongs tool life. Using water-soluble coolant is particularly effective for aluminum alloys.

How to Choose the Right Lathe?

Selecting a lathe with high precision and rigidity is important for machining 7075. Features like vibration control and accurate calibration help ensure consistent results.

Tips for Precision and Quality

To achieve the best results with Aluminum 7075, follow these precision machining tips:

How to Set Cutting Speed and Feed?

- Use slower cutting speeds to reduce tool wear.

- Optimize feed rates to balance material removal and surface quality.

What Are Good Chip Control Practices?

- Use proper chip breakers to avoid surface damage.

- Ensure efficient coolant flow to flush chips away from the cutting zone.

How to Ensure Accuracy?

Calibrate Machines

Regularly calibrate CNC machines to maintain precision and avoid deviations in part dimensions.

Control Vibrations

Minimize vibrations by using stable machine setups and balancing cutting tools properly.

Post-Turning Treatments

Post-processing is often necessary to enhance the performance of CNC-turned Aluminum 7075 components.

Why Anodize for Protection?

Anodizing creates a protective oxide layer, improving corrosion resistance and allowing for color customization.

How to Improve Corrosion Resistance?

Applying protective coatings or using chemical treatments can further enhance Aluminum 7075’s resistance to environmental factors.

Why Use Heat Treatment?

Heat treatment can improve the mechanical properties of 7075, making it even stronger and more durable for high-stress applications.

Applications of 7075 Cylindrical Parts

Aluminum 7075 is widely used for cylindrical components in various industries:

How Is 7075 Used in Aerospace?

7075 is used for aircraft parts like fuselage components and landing gear due to its high strength-to-weight ratio and durability.

Why Is 7075 Popular in Cars?

Automotive manufacturers use 7075 for performance parts like drive shafts and suspension components where strength and weight savings are critical.

Where Is 7075 Used in Tools?

7075 is commonly used in manufacturing tools such as molds and jigs, offering excellent wear resistance and precision.

FAQs About CNC Turning Aluminum 7075

What Tools Work Best for 7075?

Carbide or diamond-coated tools are ideal for machining Aluminum 7075 due to their durability and resistance to wear.

Can 7075 Be Anodized?

Yes, anodizing enhances the corrosion resistance of Aluminum 7075 while allowing for a decorative finish.

How to Avoid Tool Wear?

Use coated tools, slower cutting speeds, and apply proper coolant to reduce heat and friction.

Is 7075 Good for High-Speed Turning?

Yes, but you must manage heat and use efficient lubrication to maintain tool life and surface finish.