Soft metals and plastics are two of the most commonly used materials in CNC machining. Both offer unique properties that make them ideal for specific applications, but how do you decide which is better for your project? In this guide, we compare soft metals and plastics across various criteria, including strength, machinability, and environmental impact, to help you make an informed choice.

Obsah

- What Are Soft Metals and Plastics in CNC Machining?

- Comparing Soft Metals and Plastics for the Same Application

- Machining Soft Metals vs Plastics

- Material Performance in Real-World Applications

- Cost and Environmental Impact

- Conclusion: Which Material Suits Your Application?

- FAQs About Soft Metals and Plastics in CNC

What Are Soft Metals and Plastics in CNC Machining?

Soft metals and plastics are versatile materials often used in CNC machining due to their workability and unique properties. Here’s a closer look at each.

What Are Typical Soft Metals?

Examples: Lead, Tin, Zinc

Soft metals like lead, tin, and zinc are known for their malleability and excellent machinability. These metals are commonly used in applications requiring strength and formability.

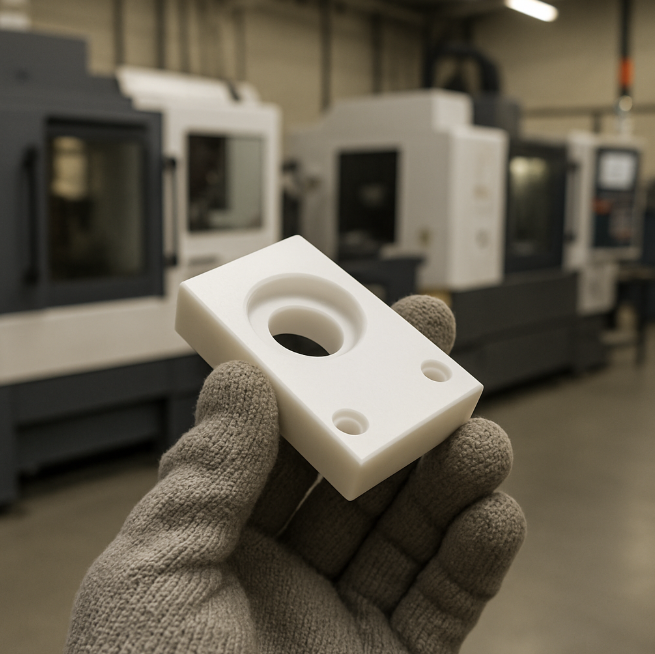

What Are Common Plastics for CNC Machining?

Examples: Nylon, PEEK, Polycarbonate

Plastics such as nylon, PEEK, and polycarbonate are lightweight, durable, and resistant to wear and chemicals. They are ideal for parts like gears, connectors, and seals.

Why Are These Materials Used in CNC Machining?

Both soft metals and plastics are easy to machine, offer diverse mechanical properties, and meet the demands of industries like automotive, aerospace, and electronics.

Comparison of Key Properties

| Majetek | Soft Metals (e.g., Zinc, Tin) | Plastics (e.g., Nylon, PEEK) |

|---|---|---|

| Hustota | High (7-11 g/cm³) | Low (1-2 g/cm³) |

| Síla | Good for load-bearing | Moderate, depends on type |

| Odolnost proti korozi | Prone to corrosion | Highly resistant |

| Obrobitelnost | Vynikající | Velmi dobře |

Comparing Soft Metals and Plastics for the Same Application

To better understand the differences, let’s compare how soft metals and plastics perform in specific use cases.

Example 1: Electrical Connectors

Soft Metal: Tin – Excellent Conductivity

Tin’s high conductivity and resistance to oxidation make it perfect for electrical connectors, ensuring reliable performance in electronics.

Plastic: Polycarbonate – Insulation and Durability

Polycarbonate offers excellent electrical insulation and impact resistance, making it suitable for non-conductive housing or connectors.

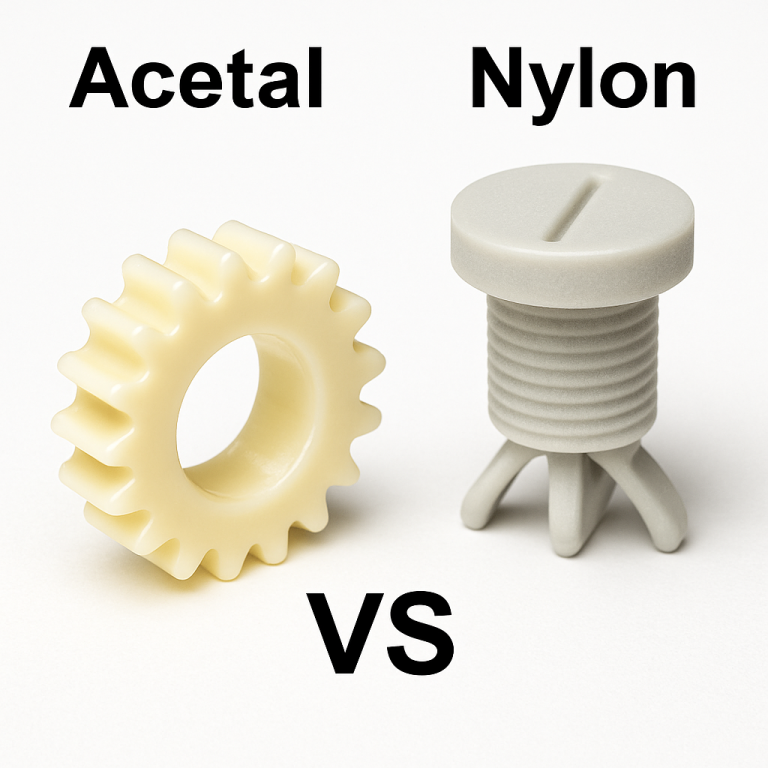

Example 2: Lightweight Gears

Soft Metal: Zinc – Strength and Machinability

Zinc is ideal for gears that require moderate strength and precise machining.

Plastic: Nylon – Quiet Operation and Self-Lubrication

Nylon gears operate quietly and have self-lubricating properties, reducing maintenance needs.

Example 3: Sealing Components

Soft Metal: Lead – Superior Malleability

Lead’s malleability makes it easy to create seals that conform tightly to surfaces.

Plastic: PEEK – High Heat and Chemical Resistance

PEEK seals excel in environments with high temperatures and aggressive chemicals.

Applications of Soft Metals and Plastics

| Aplikace | Soft Metals | Plasty |

|---|---|---|

| Electrical Connectors | Tin | Polykarbonát |

| Ozubená kola | Zinek | Nylon |

| Seals | Lead | PEEK |

Machining Soft Metals vs Plastics

Soft metals and plastics differ in machining requirements. Here’s how they compare:

Cutting Speeds and Tooling Needs

Zinc vs Nylon: Heat Management and Tool Wear

Soft metals like zinc require slower cutting speeds to manage heat, while plastics like nylon need sharp tools to prevent melting and burrs.

Surface Finish and Tolerances

Achieving Smooth Finishes on Lead vs Polycarbonate

Lead machines smoothly but is prone to deformation, while polycarbonate requires controlled speeds to avoid scratches.

Cost and Machining Efficiency

Soft metals are generally more expensive to machine due to higher material costs, while plastics offer lower costs and faster cycle times.

Material Performance in Real-World Applications

Case Study 1: Precision Bearings

Zinc vs Nylon: Wear Resistance vs Quiet Performance

Zinc bearings excel in load-bearing applications, while nylon bearings provide quieter operation and reduce friction.

Case Study 2: Lightweight Frames

Lead vs Polycarbonate: Strength vs Flexibility

Lead offers superior strength for heavy-duty frames, while polycarbonate provides flexibility and impact resistance for lightweight designs.

Case Study 3: High-Temperature Parts

Zinc vs PEEK: Heat Resistance and Chemical Stability

PEEK outperforms zinc in high-temperature environments, offering better stability and resistance to chemicals.

Cost and Environmental Impact

The cost and environmental impact of soft metals and plastics can influence material choice significantly.

Material Costs for the Same Application

Plastics are typically cheaper than soft metals, but the overall cost depends on the application and required material properties.

Recycling and Sustainability of Soft Metals vs Plastics

Soft metals like lead and tin are easily recyclable, while plastics require advanced recycling processes, making them less sustainable.

CNC Waste Management and Efficiency

Plastic waste is easier to handle due to its lightweight nature, while metal waste often requires more energy to recycle.

Conclusion: Which Material Suits Your Application?

Choosing between soft metals and plastics depends on your application’s specific requirements. Soft metals excel in strength and conductivity, while plastics offer lightweight and corrosion-resistant solutions.

Key Takeaways for Material Selection

Understand your application’s needs, whether it’s conductivity, weight, or cost-efficiency, to make the right choice between soft metals and plastics.

Why CNC Machining Supports Both Materials

CNC machining offers precision and adaptability, making it ideal for working with both soft metals and plastics efficiently.

FAQs About Soft Metals and Plastics in CNC

Which Material Is More Durable?

Soft metals like zinc are more durable under heavy loads, but plastics like PEEK resist corrosion and chemicals better.

Can Plastics Fully Replace Soft Metals?

In some cases, yes. Plastics can replace metals in lightweight and corrosion-resistant applications, but not in high-load scenarios.

What Is the Best Material for High-Temperature Parts?

PEEK is ideal for high-temperature parts, outperforming most soft metals in heat resistance.

How to Reduce Costs When Machining Both?

Optimize cutting speeds, choose cost-effective tooling, and recycle waste efficiently to reduce machining costs.