Expert Nylon CNC Machining Services

Dive deep into the capabilities of Nylon(PA) with our specialized CNC machining services. Learn how Nylon parts can improve your products from superior wear resistance to excellent mechanical properties.

Advantages and limitations of Nylon (PA)

Nylon, also known as polyamide (PA), is a versatile synthetic polymer that offers several advantages and some limitations in various applications:

| Advantages | Limitations |

|---|---|

| Strength and Durability | Moisture Absorption |

| High strength and durability, suitable for products requiring resistance to mechanical stress. | Absorbs moisture, which can cause dimensional changes and structural instability in variable humidity. |

| Flexibility | UV Sensitivity |

| Remains flexible, useful for textiles and mechanical parts like gears. | Degrades under UV exposure, leading to reduced strength and color fading. |

| Resistance to Wear and Abrasion | Temperature Sensitivity |

| Excellent wear and abrasion resistance, ideal for parts in moving systems. | Sensitive to cold, becoming brittle at low temperatures. |

| Chemical Resistance | Flammability |

| Resistant to many chemicals including hydrocarbons and oils, beneficial in chemical and automotive industries. | Flammable; melts and drips at high temperatures, needing flame retardants for safety. |

| Thermal Properties | Environmental Impact |

| Good thermal resistance, withstands higher temperatures well. | Non-biodegradable, contributing to environmental pollution if not properly recycled or disposed. |

| Moisture Absorption Enhances Pliability | |

| Moisture makes it pliable and less brittle, beneficial under certain conditions. |

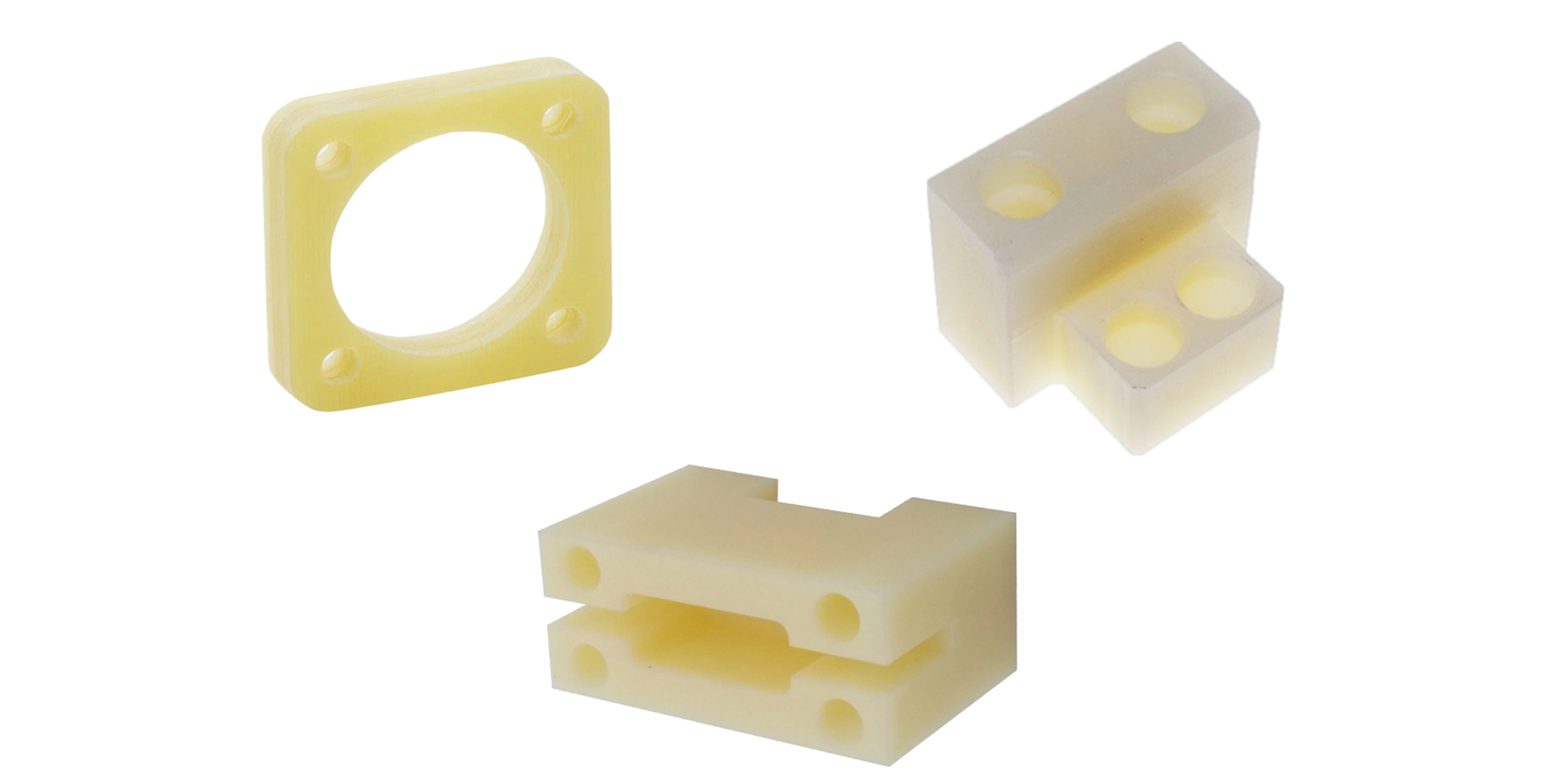

Nylon CNC Machining Parts and Used

By integrating Nylon CNC machined parts into your equipment, you can achieve higher precision and quality in your products, meeting stringent industry standards with ease.

Physical Properties of Nylon Material

Creating a detailed table of physical properties for various types of Nylon (Polyamide, PA) as used in CNC machining involves compiling data on several key material characteristics. Below, Machining Quote have structured a table that includes common 5 types of Nylon along with their respective physical properties.

| Type | Tensile Strength at Yield (MPa) | Impact Strength (kJ/m²) | Heat Deflection Temp (°C) | Coefficient of Friction | Water Absorption (% in 24h) | Chemical Resistance | Wear Resistance |

|---|---|---|---|---|---|---|---|

| Nylon 6 | 75 | No Break | 65 | 0.25 | 1.2 | Good | Excellent |

| Nylon 66 | 85 | No Break | 75 | 0.35 | 1.3 | Very Good | Excellent |

| Nylon 11 | 50 | No Break | 50 | 0.30 | 0.3 | Excellent | Good |

| Nylon 12 | 50 | No Break | 60 | 0.25 | 0.25 | Excellent | Good |

| Nylon 6/10 | 60 | No Break | 60 | 0.20 | 0.9 | Good | Good |

| Nylon 6/12 | 70 | No Break | 65 | 0.25 | 0.8 | Very Good | Good |

CNC Machining Tips for Nylon Plastic

CNC machining of nylon plastic can be quite efficient when you understand the properties of the material and the best practices to handle it. Nylon, being a versatile and durable thermoplastic, presents unique challenges and benefits in CNC machining.

| Aspect | Recommendations and Best Practices |

|---|---|

| Tool Selection | Use sharp, carbide or diamond-tipped tools to prevent material melting or deformation. |

| Cooling and Lubrication | Manage heat with coolants or compressed air; use suitable lubricants to reduce tool wear. |

| Feed Rate | Roughing: 0.3 mm to 0.6 mm per tooth. Finishing: 0.1 mm to 0.2 mm per tooth. |

| Spindle Speed | Roughing: 600 to 1000 RPM. Finishing: 1000 to 1500 RPM. |

| Chip Removal | Ensure efficient chip clearance to prevent re-welding of chips to the part, impacting finish and accuracy. |

| Support and Fixturing | Use soft jaws for clamping; adequately support material without over-tightening. Plan for material deformation. |

| Post-Processing | Allow parts to cool down gradually; consider sanding or flame polishing for smooth finishes. |

| Dimensional Accuracy | Account for potential shrinkage due to internal stress relief. Design parts with appropriate tolerances. |

| Environmental Considerations | Control humidity as nylon absorbs moisture, affecting mechanical properties and dimensional stability. Allow material to acclimate before machining. |

| Tool Path Strategy | Prefer climb milling for improved surface finish and reduced tool load. |

CNC Turning and CNC Milling for Nylon Parts

When CNC with nylon parts, using CNC turning and milling can give you great results.

Post Processing Service

Post-processing services for nylon parts are essential to achieving the desired surface finish, dimensional accuracy, and functional performance. Here are some common post-processing techniques that are particularly effective for nylon components:

Nylon is relatively easy to machine but requires care due to its flexibility, low melting point, and moisture absorption. Proper tooling, cooling, and handling mitigate issues like deformation and burring.